Product Categories

Product Tags

Low-Voltage PTC Thermostatic Heater

PTC heaters are heating devices designed to utilize the constant-temperature heating characteristics of low-voltage PTC thermostatic heaters. In low- and medium-power heating applications, PTC heaters offer advantages unmatched by traditional heating elements, including constant temperature heating, no open flame, high heat conversion efficiency, minimal influence from power supply voltage, and a long lifespan. Their use in electric heating appliances is increasingly favored by R&D engineers.

Product Overview

Low-voltage PTC thermostatic heaters require only 3-24V voltage to maintain constant temperature heating. Their principle is that when power is applied, the PTC thermistor’s self-heating causes its resistance to enter the transition region, maintaining a constant surface temperature. This temperature is dependent solely on the PTC thermistor’s Curie temperature and the applied voltage, and is largely independent of the ambient temperature.

PTC heaters are heating devices designed to utilize the constant-temperature heating characteristics of low-voltage PTC thermostatic heaters. In low- and medium-power heating applications, PTC heaters offer advantages unmatched by traditional heating elements, including constant temperature heating, no open flame, high heat conversion efficiency, minimal influence from power supply voltage, and a long lifespan. Their use in electric heating appliances is increasingly favored by R&D engineers.

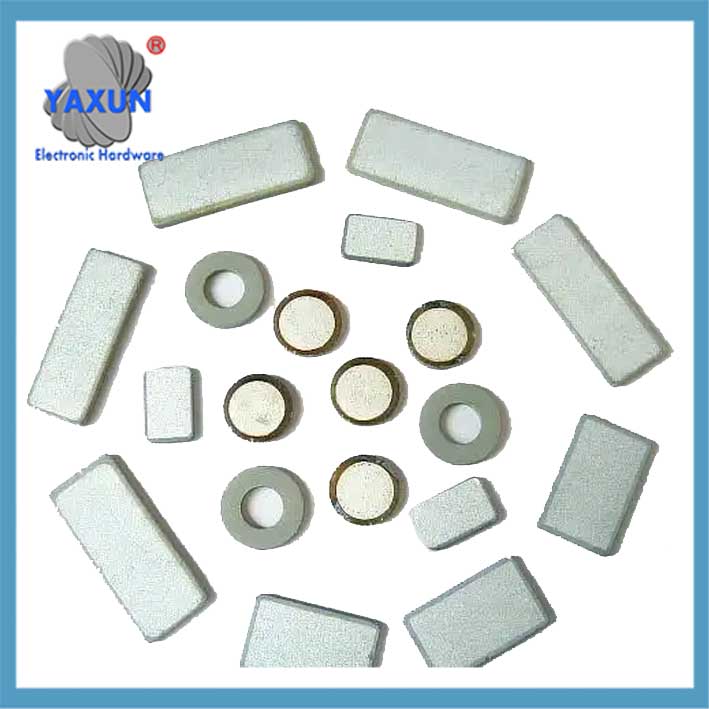

PTC thermistors for constant-temperature heating can be manufactured in a variety of shapes and specifications. Common shapes include discs, rectangles, strips, rings, and honeycomb structures. Combining these PTC heating elements with metal components can create various high-power PTC heaters. Note: High-power, low-voltage PTC thermostatic heaters have very high power requirements. For example, a 500W heater with a 12V supply draws a normal operating current of 500 ÷ 12 = 41.67A. Therefore, the power supply must be capable of supplying at least 50A.

Application Design

Utilizing the constant-temperature heating principle of PTC thermistors, applications include hair straighteners, hair clips, hair clips, ion perms, perms, perms, ceramic perms, hair tongs, curling irons, electric combs, negative ion hair curlers, massagers, mosquito repellents, mosquito coil dispensers, fragrance dispensers, perfume dispensers, hot melt glue guns, foot bath heating, thermos cups, water heaters, coffee makers, coffee warmers, coffee heaters, water dispensers, hot and cold water dispensers, milk heaters, shower heating, electric mosquito repellents, hand warmers, dryers, electric hot plates, electric irons, electric soldering irons, electric adhesives, hair curlers, showers, shoe dryers, shoe dryers, foot warmers, electric heating plates, spectrum analyzers, spectrum therapy, physical therapy devices, infrared heating, motorcycle carburetors, electric humidifiers, and moisture-proof heating for electrical instruments. Constant temperature incubators, electronic thermos bottles, insulated boxes, insulated cups, insulated trays, insulated cabinets, electric hot plates, thermotherapy devices, coffee makers, wax melters, steam generators, humidifiers, chocolate extruders, soldering irons, acupuncture equipment, urinary catheters, foot warmers, hand dryers, cotton candy machines, massagers, small warm air heaters, hair dryers, control cabinet heating and moisture-proofing systems, monitors, electric ovens, toaster ovens, IV drip kits, medical equipment, household appliances, small appliances, and more.

Low-voltage PTC heaters

Appearance and Structure

| Model | Rated Temperature Resistance 25℃/Ω |

Surface Temperature /℃ |

Rated Voltage /V |

Length L/mm |

Width W/mm |

Thickness T/mm |

| MZ9-L35W6T2.1V12T60 | 10~30 | 60±10 | 12 | 35 | 6 | 2.1 |

| MZ9-L35W6T2.1V12T70 | 10~30 | 70±10 | 12 | 35 | 6 | 2.1 |

| MZ9-L35W5T2.1V12T180 | 10~30 | 180±10 | 12 | 35 | 5 | 2.1 |

| MZ9-L35W5T2.1V12T240 | 10~30 | 240±10 | 12 | 35 | 5 | 2.1 |

| MZ9-L35W5T2.1V12T270 | 10~40 | 270±10 | 12 | 35 | 5 | 2.1 |

| MZ9-L24W15T1.15V12T120 | 2~12 | 120±10 | 12 | 24 | 15 | 1.15 |

| MZ9-L24W15T1.15V12T140 | 2~12 | 140±10 | 12 | 24 | 15 | 1.15 |

| MZ9-L24W15T1.15V12T180 | 2~12 | 180±10 | 12 | 24 | 15 | 1.15 |

| MZ9-Φ5T1.1V12T50 | 80~150 | 50±5 | 12 | Φ5 | 1.1 | |

| MZ9-Φ10T1.2V12T70 | 5~30 | 70±10 | 12 | Φ10 | 1.2 | |

| MZ9-Φ13T2.5V12T80 | 10~30 | 80±10 | 12 | Φ13 | 2.5 | |

| MZ9-Φ8T1.85V12T90 | 10~30 | 90±10 | 12 | Φ8 | 1.85 | |

| MZ9-Φ6T1.85V12T100 | 10~30 | 100±10 | 12 | Φ6 | 1.85 | |

| MZ9-Φ10T2.5V12T120 | 10~30 | 120±10 | 12 | Φ10 | 2.5 | |

| MZ9-Φ16T1.1V12T160 | 2~30 | 160±10 | 12 | Φ16 | 1.1 | |

| MZ9-Φ20T1.5V12T200 | 2~30 | 200±10 | 12 | Φ20 | 1.5 |

Temperatures can be designed between 50°C and 200°C, and operating voltages can be designed between 3V and 50V, depending on customer requirements.

Notes on Use

1) The PTC heater features automatic constant temperature control, eliminating the need for a temperature control system. It is the core component of all PTC heaters.

2) Four electrode types are available: electroless nickel + silver, melt-blown aluminum, printed aluminum + silver, and printed aluminum.

3) Unlike products designed for mains voltage, low-voltage products experience significant surface temperature fluctuations when the operating voltage fluctuates by more than 25%.

4) When multiple PTC heaters are used together, they should be connected in parallel, not in series.

5) This product does not have lead wires or insulation. If this is not feasible, please select a model with an external insulation film or a metal-cased model.

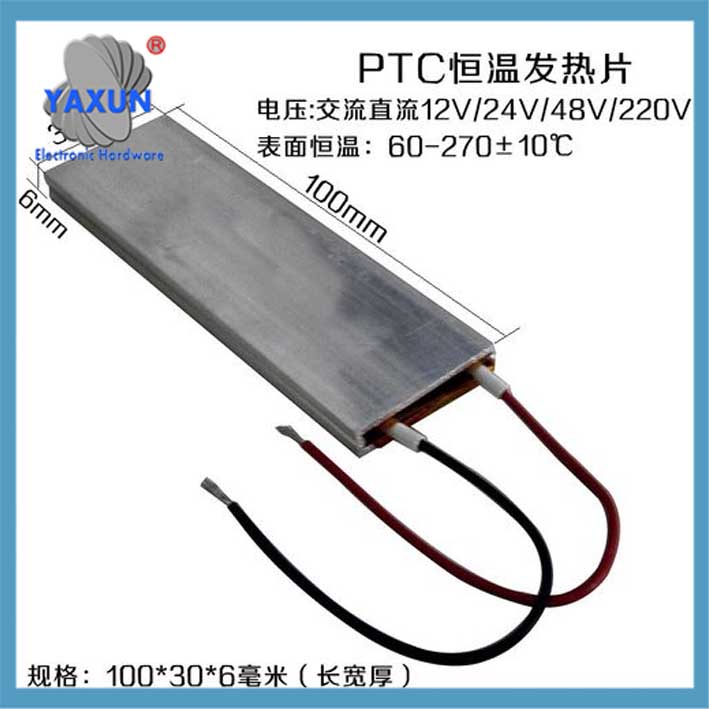

Low-Voltage Metal-Cased PTC Heater

Appearance and Structure

Notes on Use

1) The heating power decreases gradually after power is applied, eventually stabilizing. Stable power depends on operating conditions. The power of the same PTC heater can vary several times depending on the operating conditions. The faster the heat dissipation, the greater the stable power; the higher the PTC surface temperature, the higher the power.

2) The surface temperature of the PTC heater is controlled by the PTC itself and can be controlled by disconnecting the circuit, but it cannot be controlled by adjusting the voltage.

3) PTCs are inherently highly reliable and have a long lifespan, but improper assembly can cause power and temperature instability.

4) When using multiple PTCs, they should be connected in parallel, not in series.

We can design the temperature range from 50°C to 280°C and the operating voltage range from 3V to 50V according to customer requirements.

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt