Product Categories

Product Tags

Functions and Applications of Electronic Fuses (eFuses)

Electronic fuses (eFuses) are solid-state devices that protect electronic circuits from overcurrent conditions. Unlike traditional fuses, they can be electronically reset, offering a more convenient and efficient solution for circuit protection. eFuses protect against short circuits, overloads, and other fault conditions, preventing damage to devices and wiring.

A efuse (also called a efuse link) is an electronic component used to protect a circuit from overcurrent or overheating. Its core function is to automatically blow in abnormal situations to cut off the circuit. The following are its key points:

I. Core Principle and Structure

Working Principle

When the current rises abnormally, the conductor heats up due to resistance (following the formula Q=I2RTQ=I2RT), and when it reaches the melting point of the melt material, it melts automatically, thereby cutting off the circuit.

Basic Structure

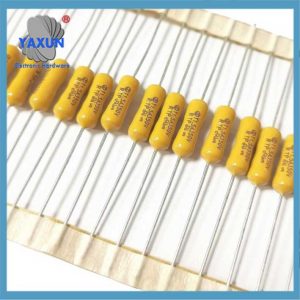

Melt Material: Lead-antimony alloy (low melting point, high resistivity) was used in the early days, and silver, copper or special alloys are mostly used in modern times.

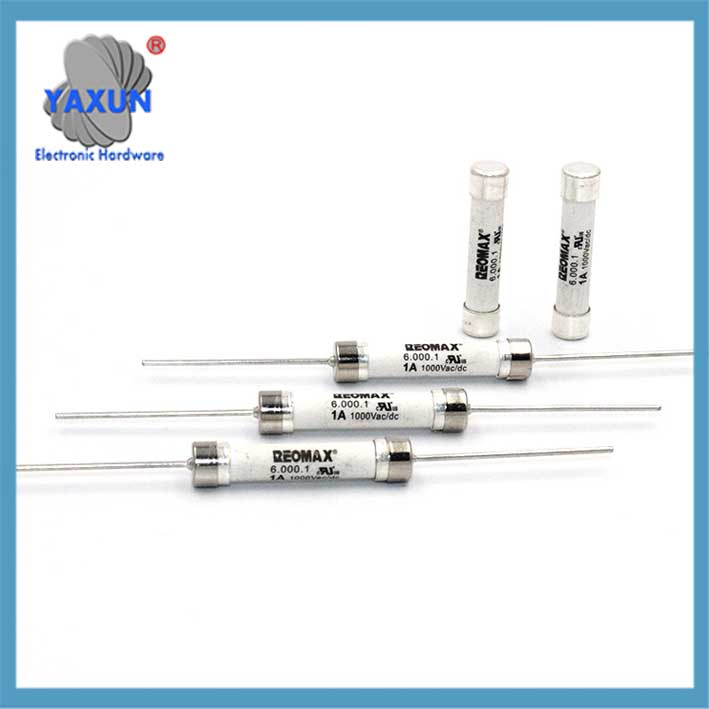

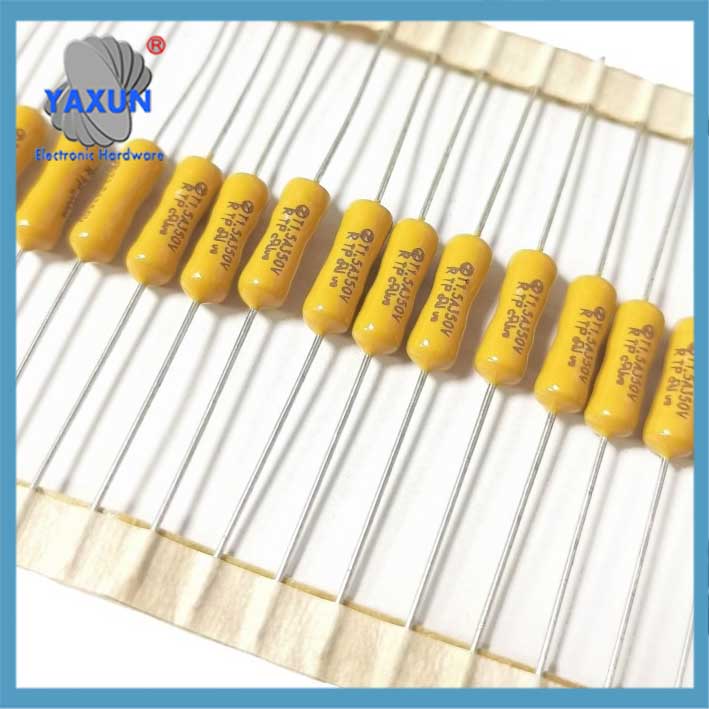

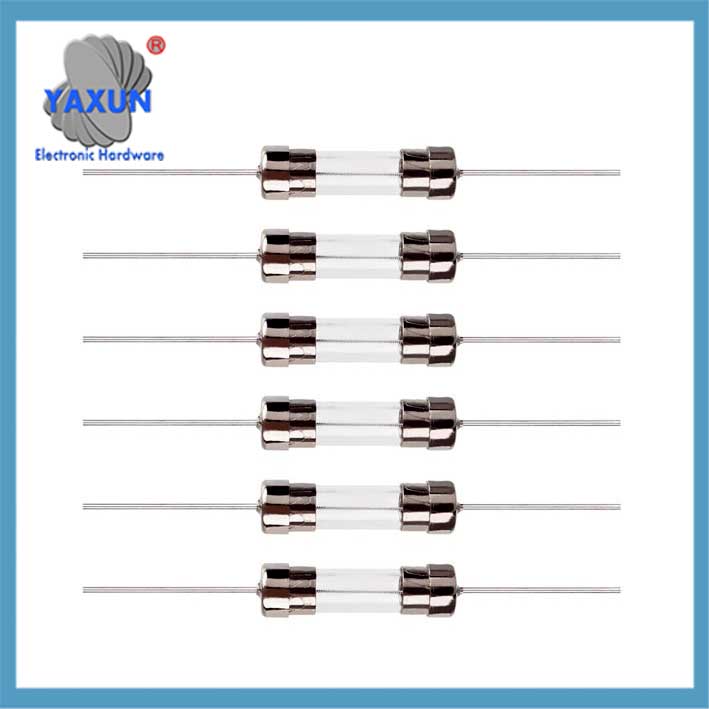

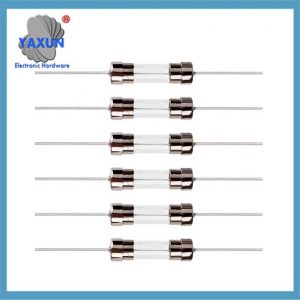

Packaging Form: Including glass tubular (such as 5×20mm, 6×32mm, 3.6×10mm), ceramic tubular, sheet (for automobiles), SMD patch type, etc.

Overcurrent Protection:

eFuses interrupt the flow of current when it exceeds a predetermined threshold, preventing damage to sensitive electronic components.

Short Circuit Protection:

They quickly detect and interrupt short circuits, which are low-resistance paths that cause excessive current flow.

Overload Protection:

eFuses safeguard against prolonged overcurrent conditions, such as those caused by a mismatched load.

Fault Detection and Isolation:

They can be designed to detect and isolate various fault conditions, including inrush currents, overvoltage, reverse current, and reverse polarity.

Self-Resetting:

Many eFuses can be reset electronically, allowing them to return to normal operation after a fault condition is cleared, eliminating the need for physical replacement.

Adjustable Slew Rate:

Some eFuses offer adjustable slew rates, allowing for control over the speed at which the current rises, which can be useful in preventing damage from inrush currents.

III. Classification and Application Scenarios

| Type | Features | Typical applications |

|---|---|---|

| Fast-blow type | Extremely fast response (<0.001 seconds), used in sensitive circuits | Semiconductor equipment, precision electronic products |

| Slow-blow type | Allows short-term overload (0.01–0.1 seconds to blow), surge current resistance | Motor starting circuit, power adapter |

| Temperature fuse | Inductive overheating, single-use | Heating appliances such as hair dryers and rice cookers |

| High-voltage fuse | Includes mounting components (such as clamping springs) to simplify pipe connection | High-voltage power system |

Applications of Electronic Fuses:

Automotive Electronics:

eFuses are used in various automotive systems, including engine control units, infotainment systems, and safety systems.

Industrial Automation:

They are utilized in programmable logic controllers (PLCs), motor control systems, and other industrial automation equipment.

Consumer Electronics:

eFuses are found in smartphones, laptops, tablets, and other portable devices.

Data Centers:

They are used in power distribution units and server racks to protect critical infrastructure.

Hot-Swap Systems:

eFuses provide protection in systems where components can be added or removed while the system is running.

Battery Management Systems:

They are used in battery charging and discharging circuits to prevent overcurrent and overvoltage conditions.

Power Distribution:

eFuses are used in power distribution units and power supplies to protect against overcurrents and short circuits.

General Circuit Protection:

eFuses can be used in any electronic circuit where overcurrent protection is needed.

III. Key usage specifications

Prohibited substitution of materials

Copper wire or iron wire cannot be used as a substitute (low resistivity, high melting point), which may cause an accident due to failure to blow in time.

Selection factors

Rated current: It needs to be slightly higher than the maximum working current of the circuit (such as 6A fuse for 5A circuit).

Breaking capacity: It must be greater than the maximum short-circuit current of the circuit (such as 100A short circuit, ≥100A breaking capacity).

Ambient temperature: Derating is required for high temperature environment.

IV. Technological progress

Automated detection: Such as material transfer components + machine vision detection device, to improve the efficiency of fuse production and sorting.

Structural optimization: High-voltage fuses adopt a clamping spring design to simplify the installation process.

Note: After the fuse is blown, it needs to be replaced with a new product of the same specification. For glass tube models, the fuse status can be visually observed to determine whether it is invalid.

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt