Produktų kategorijos

- Šilumos saugiklis 32

- Paviršiaus laikikliai 12

- Termistorius 36

- PCB kalno saugiklių laikiklis 27

- Laidų diržai 6

- Ašmenų saugiklių laikikliai 17

- Termostatas 50

- Elektrinis saugiklis 24

- Automobilių temperatūros jutiklis 7

- Šilumos grandinės pertraukiklis 22

- „Fuse Box Holder“ 36

- Temperatūros jutiklis 75

- Šiluminis jungiklis 68

- Automobilių saugiklis 20

- Varžtas žemyn 8

Produktų žymos

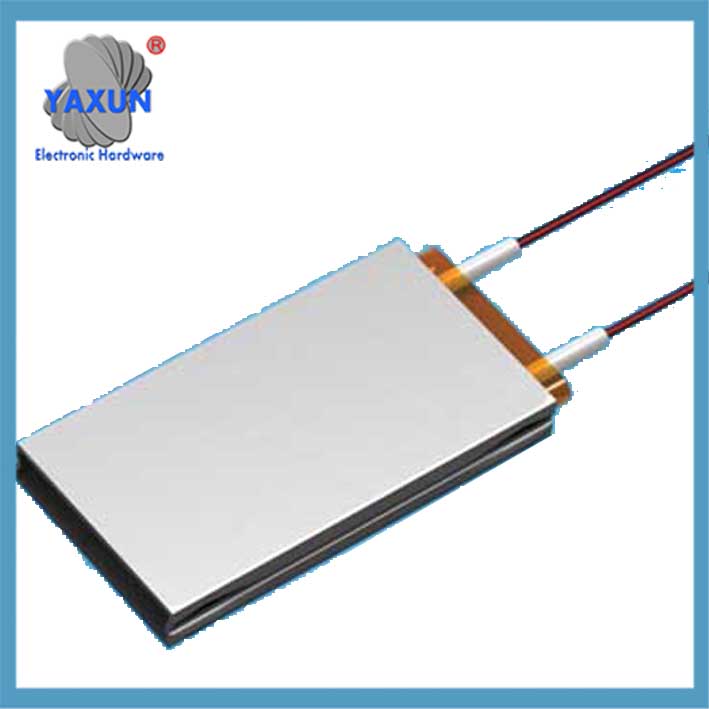

PTC termistoriai pastovios temperatūros šildymui

PTC pastovios temperatūros šildytuvai yra šildymo įrenginiai, skirti naudoti PTC termistorių pastovios temperatūros šildymo charakteristikas. Žemai- ir vidutinės galios šildymo programos, PTC šildytuvai turi pranašumų prieš tradicinius šildymo elementus, pavyzdžiui, pastovios temperatūros šildymas, jokios atviros liepsnos, Didelio šilumos konversijos efektyvumas, Minimalios maitinimo įtampos įtaka, ir ilga gyvenimo trukmė. Jų naudojimą elektriniuose šildymo prietaisuose vis labiau palankiai vertina r&D inžinieriai.

Produkto apžvalga

The constant temperature heating characteristics of PTC thermistors for constant temperature heating are determined by the material properties. The principle is that when power is applied to the PTC thermistor, self-heating causes the component’s temperature to rise, causing the resistance value to enter the transition region and the current to drop rapidly. Consequently, the surface temperature of the PTC thermistor remains constant. Ši temperatūra priklauso tik nuo PTC termistoriaus „Curie“ temperatūros ir taikomos įtampos, ir iš esmės nepriklauso nuo aplinkos temperatūros.

PTC pastovios temperatūros šildytuvai yra šildymo įrenginiai, skirti naudoti PTC termistorių pastovios temperatūros šildymo charakteristikas. Žemai- ir vidutinės galios šildymo programos, PTC šildytuvai turi pranašumų prieš tradicinius šildymo elementus, pavyzdžiui, pastovios temperatūros šildymas, jokios atviros liepsnos, Didelio šilumos konversijos efektyvumas, Minimalios maitinimo įtampos įtaka, ir ilga gyvenimo trukmė. Jų naudojimą elektriniuose šildymo prietaisuose vis labiau palankiai vertina r&D inžinieriai.

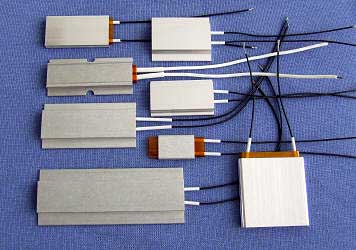

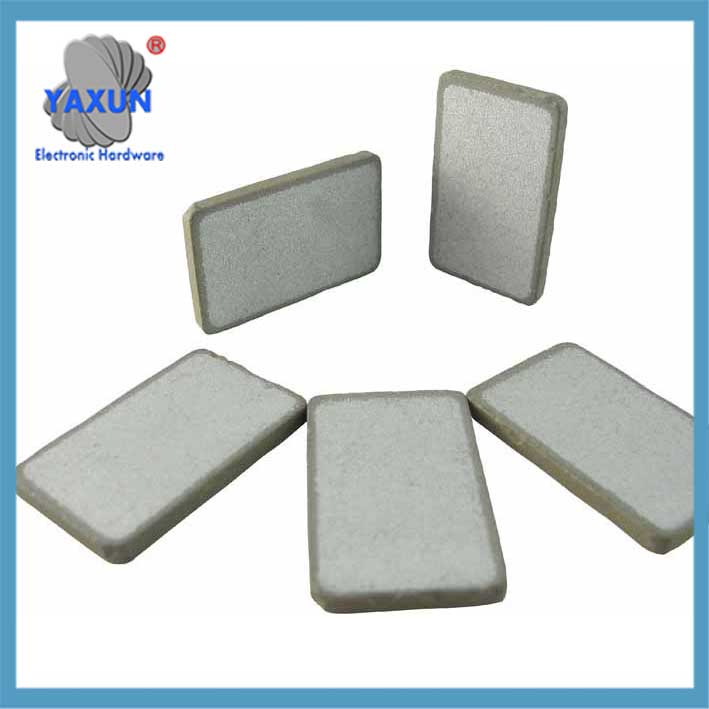

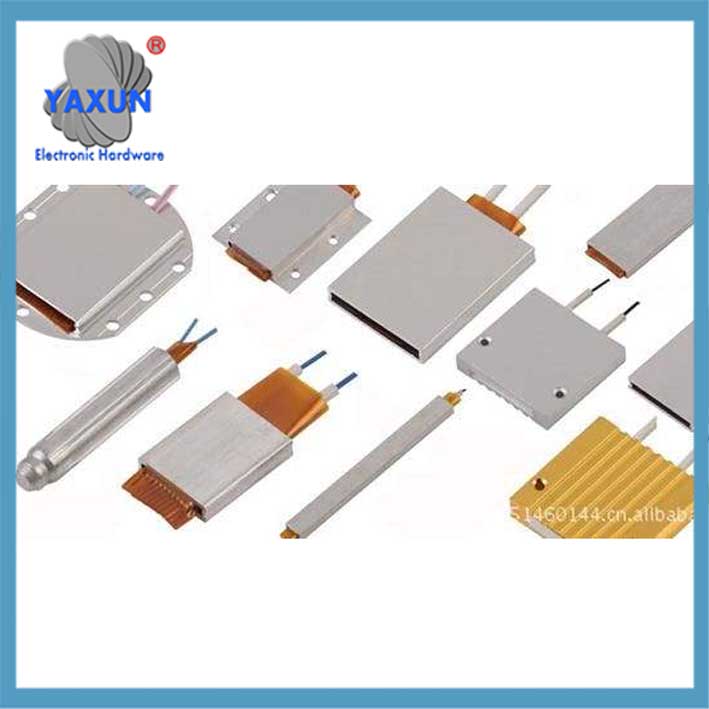

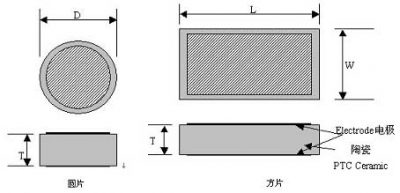

PTC thermistors for constant temperature heating can be manufactured in a variety of shapes and specifications. Įprastas formas sudaro diskai, stačiakampiai, juostelės, Žiedai, and honeycomb pores. Combining the above-mentioned PTC heating elements with metal components can create various high-power PTC heaters.

Taikymo dizainas

Naudojant PTC termistorių nuolatinio temperatūros kaitinimo principą, these devices can be designed for applications such as hair straighteners, Plaukų spaustukai, Plaukų spaustukai, leidimai, leidimai, Keraminiai perms, plaukų žnyplės, garbanojimo lygintuvai, Elektrinės šukos, neigiamos jonų plaukų suktukai, Massagers, uodų repelentai, uodų repelentai, Mosquito ritės balionėliai, Kvapų dozatoriai, kvepalų balionėliai, karštų lydymosi klijų pistoletai, heated foot baths, laminavimo mašinos, „Thermos“ puodeliai, water boilers, Kavos mašinos, Kavos šildytuvai, Kavos šildytuvai, Vandens balionėliai, Karšti ir šalto vandens balionėliai, Pieno šildytuvai, Vandens šildytuvai, shower heaters, Elektriniai uodai repelentai, rankų šildytuvai, džiovintuvai, Elektrinės karštos plokštelės, elektriniai lygintuvai, Elektrinis litavimo lygintuvai, electric thermal adhesives, garbanojimo lygintuvai, dušai, fan heaters, drying rooms, elektriniai šildytuvai, elektriniai šildytuvai, air conditioning systems, air conditioning heating systems, space heaters, air heating systems, hot water kettles, Batų džiovintuvai, shoe drying devices, Kojų šildytuvai, Elektrinės šildymo plokštelės, Spektro analizatoriai, Spektro terapija, Fizinės terapijos prietaisai, infraraudonųjų spindulių šildymas, drabužių džiovintuvai, Motociklų karbiuratoriai, elektriniai drėkintuvai, drėgmei atsparus elektrinių instrumentų šildymas, small crystal device constant temperature baths, pastovios temperatūros inkubatoriai, Elektroniniai termoso buteliai, Izoliuotos dėžutės, Izoliuoti puodeliai, Izoliuoti dėklai, Izoliuotos spintelės, insulated tables, Elektrinės šildymo plokštelės, terminės terapijos prietaisai, karštos kavos aparatai, garų grožio procedūros, Vaško lydyklos, Garo generatoriai, drėkintuvai, drėkintuvai, Šokolado ekstruderiai, hot packs, Elektrinis litavimo lygintuvai, akupunktūra, Šlapimo kateteriai, Kojų šildytuvai, Rankų džiovintuvai, Medvilnės saldainių mašinos, Massagers, liquefied gas cylinder heating, maži šilto oro šildytuvai, Plaukų džiovintuvai, patalpų šildytuvai, džiovintuvai, sausos spintos, drabužių džiovintuvai, pramoninė džiovinimo įranga, Electric dust collector hopper heater, train locomotive electric heater, pelėsių šildymas, valdymo spintos šildymas atsparus drėgmei, monitorius, atsparus drėgmei, elektrinė orkaitė, elektrinis skrudintuvas, infusion box, Medicinos įranga, buitiniai prietaisai, kasdieniniai prietaisai, Maži prietaisai…ir tt.

Model Parameters

| Ring Temperature Resistance 25℃/h |

Paviršiaus temperatūra /℃ |

Maksimali įtampa /V |

Skersmuo D/mm |

Ilgis L/mm |

Plotis W/mm |

Storis T/mm |

| 500~1500 | 50 | 270 | 8 | 3 | ||

| 300~800 | 85 | 140 | 16 | 11 | 2.5 | |

| 150~400 | 90 | 140 | 16 | 11 | 2.5 | |

| 600~1500 | 100 | 270 | 20 | 2.5 | ||

| 500~1500 | 110 | 270 | 16 | 11 | 2.2 | |

| 500~1500 | 130 | 270 | 20 | 2.2 | ||

| 200~800 | 150 | 140 | 10.8 | 2.2 | ||

| 200~800 | 155 | 270 | 10.8 | 2.2 | ||

| 500~1500 | 155 | 270 | 10.8 | 2.2 | ||

| 1.5~5 tūkst | 170 | 140 | 5 | 4 | 1.6 | |

| 150~500 | 175 | 140 | 10.8 | 2.2 | ||

| 500~1500 | 180 | 270 | 10.8 | 2.2 | ||

| 200~800 | 185 | 270 | 10.8 | 2.2 | ||

| 1~3 tūkst | 195 | 270 | 8 | 2.5 | ||

| 800~2 tūkst | 230 | 270 | 19 | 12 | 2.2 | |

| 800~2 tūkst | 250 | 270 | 13 | 2.5 | ||

| 2~5 tūkst | 250 | 270 | 20 | 2.5 | ||

| 300~1 tūkst | 250 | 140 | 23.5 | 10 | 2.2 | |

| 800~2 tūkst | 255 | 270 | 23.5 | 10 | 2.2 | |

| 500~2 tūkst | 275 | 270 | 35 | 10 | 2.1 | |

| 300~800 | 280 | 140 | 24 | 15 | 2.5 | |

| 0.8~3,5 tūkst | 280 | 270 | 24 | 15 | 2.5 |

Naudojimo pastabos

1) PTC šildytuvas pasižymi automatiniu konstantos temperatūros valdymu, pašalinti temperatūros valdymo sistemos poreikį. Tai yra pagrindinis visų PTC šildytuvų komponentas.

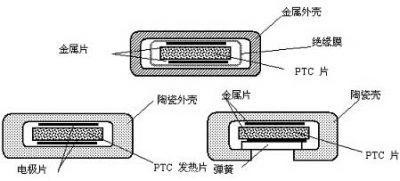

2) Galimi keturi elektrodų tipai: Elektroliiškas nikelis + sidabras, lydymosi išpūstas aliuminis, spausdintas aliuminis + sidabras, ir atspausdintas aliuminis.

3) The operating voltage range is very wide. Even with a 2x increase in operating voltage, the surface temperature changes minimally.

4) Kai kartu naudojami keli PTC šildytuvai, Jie turėtų būti sujungti lygiagrečiai, ne serijose.

5) Šis produktas neturi švino laidų ar izoliacijos. Jei tai neįmanoma, please select a model with an external insulation film or a metal housing.

Model Parameters

| Ilgis/mm | Plotis/mm | Storis/mm | Surface Temperature/℃ | Insulation Withstand Voltage/V | Operating Voltage/V |

| 30~120 | 20 | 5.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 30 | 6.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 33 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 35 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 40 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 43 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 46 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 56 | 7.0 | 60~280 | 3750 | 100~240 |

Temperatures can be designed between 60°C and 280°C, and operating voltages can be designed between 12V and 240V, priklausomai nuo klientų reikalavimų.

Usage Precautions

1) After power is applied, the heating power decreases gradually and then stabilizes. Stabili galia priklauso nuo darbo sąlygų. The power of the same PTC heater can vary several times depending on operating conditions. Tuo greitesnis šilumos išsisklaidymas, tuo didesnė stabili galia; Kuo aukštesnė PTC paviršiaus temperatūra, Kuo didesnė galia.

2) PTC šildytuvo paviršiaus temperatūra yra kontroliuojama pati PTC ir gali būti valdoma atjungus grandinę, but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) Kai naudojate kelis PTC, Jie turėtų būti sujungti lygiagrečiai, ne serijose.

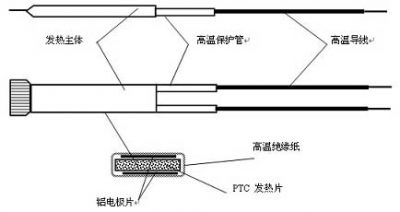

Model Parameters

| Ilgis (mm) | Plotis (mm) | Storis (mm) | Paviršiaus temperatūra (° C.) | Insulation Withstand Voltage (V) | Operating Voltage (V) |

| 24 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 24 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 above | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

Temperatures can be designed between 50°C and 280°C, and operating voltages can be designed between 3V and 240V, priklausomai nuo klientų reikalavimų.

Usage Precautions

1) After power is applied, the heating power decreases gradually and then stabilizes. Stabili galia priklauso nuo darbo sąlygų. The power of the same PTC heater can vary several times depending on operating conditions. Tuo greitesnis šilumos išsisklaidymas, tuo didesnė stabili galia; Kuo aukštesnė PTC paviršiaus temperatūra, Kuo didesnė galia.

2) PTC šildytuvo paviršiaus temperatūra yra kontroliuojama pati PTC ir gali būti valdoma atjungus grandinę, but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) Kai naudojate kelis PTC, Jie turėtų būti sujungti lygiagrečiai, ne serijose.

Susisiekite su mumis

Laukiu jūsų el. Pašto, Mes jums atsakysime 12 Valandos su vertinga informacija, kurios jums reikėjo.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt