To ensure that the motor thermal protector is correctly installed and operates reliably, the following are key installation steps and precautions based on the motor type and application scenario:

🔧 I. Core Installation Steps

Locate the Protector:

Determine the best placement for the thermal protector based on the motor’s design and the operating environment. It should be positioned to accurately monitor heat generation.

Wiring:

Carefully follow the manufacturer’s wiring diagrams to ensure correct and secure connections. Incorrect wiring can lead to malfunctions or false readings.

Protection Settings:

Adjust the temperature limit on the protector according to the motor’s design and the operating environment. This ensures that the protector shuts down the motor before it overheats.

Secure Installation:

Ensure the protector is securely mounted and that no wires are exposed or damaged.

Testing:

After installation, test the thermal protector to verify that it trips at the correct temperature setting.

Important Considerations:

Safety: Always disconnect power before working on any electrical equipment.

Overload Protection: Ensure the thermal protector is properly set to prevent overloads, which can damage the motor.

Consult Documentation: Refer to the manufacturer’s documentation for specific instructions and wiring diagrams.

By following these steps, you can ensure that your motor thermal protector is installed correctly and effectively protects the motor from overheating.

Power-off operation

Before installation, the main power must be cut off and the power must be checked to prevent electric shock accidents.

Determine the installation position

Conventional motor: Connect in series between the contactor output and the motor input (main circuit);

Star-delta starting motor: Preferentially install at the top of the main circuit to ensure full current monitoring.

Wiring specification

Power line→Connect to the protector input (marked “IN” or “L”);

Motor line→Connect to the output (marked “OUT” or “T1/T2”);

Lead wire processing: The bending point is ≥6mm from the root to avoid damage to the wire.

Fixed method

Anti-loosening washers are required when fixing with screws/rivets to prevent mechanical creep from causing poor contact.

Functional test

After power is restored, use a multimeter to detect the connectivity of the input and output terminals to simulate overheating to trigger a power-off response.

⚠️ II. Key pitfall avoidance guide

| Wrong operation | Correct method | Risk warning |

| Forced bending at the root of the lead | Gently bend 6mm away from the root | Protection failure caused by lead breakage |

| Thermal element on the side of the bimetal | The heating element is placed directly below the bimetal (accelerates heat conduction) | Action delay burns the motor |

| Not cooled after welding | Forced cooling ≥30 seconds after welding | Thermistor characteristic drift |

| Not selected according to the motor type | Delta motor must select differential phase loss protection type (such as JR20) | Protection blind area when phase is lost |

🔌 III. Precautions for special scenarios

Automobile motor

Disable pure mechanical protectors, and give priority to smart modules with integrated LIN bus (such as TI DRV5013) to avoid interference with the anti-pinch function.

Variable frequency motor

The protector needs to be >50cm away from the inverter, and the shielded wire is grounded to suppress electromagnetic interference.

Micro motor (such as drone)

Built-in PTC protectors (such as Murata POSISTOR®) need to be directly attached to the windings, and thermal grease should be applied to improve heat conduction efficiency.

Appendix: Setting current specification

Stable running motor: Setting current = motor rated current × (0.95~1.05)

Frequent start and stop motor: Setting current = rated current × 1.2 (need to cooperate with time relay)

✅ Acceptance standard

After manually triggering the protector, the contactor should trip within 0.5 seconds;

After continuous operation for 72 hours, the terminal temperature rise is ≤40K;

After the vibration test (ISO 16750), the protection function is normal.

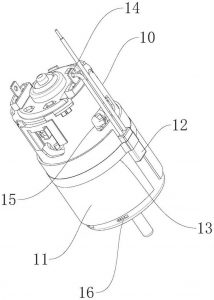

Installation diagram example:

plaintext Copy Code

[Power] → [Circuit breaker] → [Contactor] → [Thermal protector] → [Motor]

↑

[Control circuit] ← [Protector auxiliary contact]

Note: The arrow points to the current direction

Following this process can avoid 90% of installation failures. It is recommended to check the oxidation of the contacts every month after the first installation.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt