Produktkategorien

- Thermosicherung 32

- oberflächenmontierte Sicherungen 12

- Thermistor 36

- Sicherungshalter für Leiterplattenmontage 27

- Kabelbaum 6

- Flachsicherungshalter 17

- Thermostat 50

- Elektro-Sicherung 24

- Kfz -Temperatursensor 7

- Thermischer Schutzschalter 22

- Sicherungskastenhalter 36

- Temperatursensor 75

- Thermischer schalter 68

- Autosicherung 20

- Sicherungen festschrauben 8

Produkt Tags

PTC-Thermistoren für Energiesparlampen und Vorschaltgeräte

PTC-Thermistoren werden in elektronischen Vorschaltgeräten und Energiesparlampen als Vorheiz- und Sanftanlaufgeräte eingesetzt. Sie können die Zyklenzahl und Lebensdauer von Lampen deutlich erhöhen. “Yaxun” widmet sich seit mehr als zehn Jahren der Forschung und Produktion von Vorheiz- und Sanftanlauf-PTC-Thermistoren, umfangreiche Erfahrungen sammeln. Im Einklang mit der Geschäftsphilosophie von “Integrität als Grundlage, Innovation als Priorität,” Wir bieten unseren Kunden stabile und zuverlässige Produkte, Wir gewinnen das Vertrauen unserer Kunden. Unsere Thermistoren werden von weltbekannten Elektrobeleuchtungsunternehmen wie Philips verwendet, GE (China), IKEA, Megaman, Osram (China), und TCL. Mit einer jährlichen Produktion und einem überdurchschnittlichen Umsatz 100 Millionen Einheiten, Wir halten einen führenden Marktanteil unter unseren Mitbewerbern im In- und Ausland.

PTC thermistors are primarily used in energy-saving lamps and electronic ballasts for the “preheat soft start” Funktion, significantly improving lamp life and energy efficiency. Im Folgenden sind ihre Kernanwendungen und technischen Highlights aufgeführt:

ICH. Operating Principle

Cold, Low-Resistance Phase

When the circuit is started, the PTC is at room temperature and has a low resistance (Z.B., 30-60Oh). Current flows through the PTC to preheat the filament (typically taking 0.4-2 seconds to reach an operating temperature of 1160K), preventing direct high-voltage shock from causing sputtering and filament loss.

Hot, High-Resistance Phase

When the PTC temperature reaches the Curie point (Z.B., 75°C-105°C), its resistance suddenly increases (to several thousand ohms). Current is diverted to the resonant circuit, generating high voltage to ignite the lamp, completing the soft start process.

Ii. Core Advantages

Extended Lamp Life: Preheat start increases lamp life by 4-5 mal.

Reduced Electrical Stress: Reduces the impact of sudden high voltage on electronic components.

Self-Recovery: Automatically resets after the fault is resolved, eliminating the need for replacement.

III. Selection parameters and model examples

| Parameter | Typical Values/Range | Applicable Scenarios |

|---|---|---|

| Steady-State-Widerstand | 30-300Oh | Low resistance reduces warm-up delay |

| Curie-Temperatur | 75℃-105℃ | Compatible with lamps of varying wattages |

| Durchmesser | 4mm-12mm | Select based on circuit space |

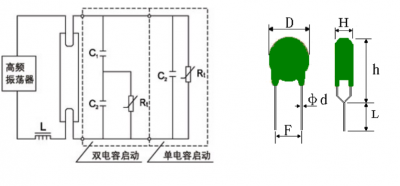

Application Diagram

As shown in the figure: When the circuit is initially connected, Rt is at room temperature, its resistance far lower than that of C2. Current flows through C1, and Rt forms a circuit to preheat the filament. After approximately 0.4-2 Sekunden, Rt’s temperature exceeds the switch temperature, Tsw, and enters a high-resistance state. Its resistance is much higher than the impedance of C2. Current flowing through C1 and C2 forms a loop, causing LC resonance and generating high voltage, which illuminates the lamp.

Common Models:

MZ4/MZ5: Suitable for small and medium-power CFLs (18W-72W).

WMZ11A: Dedicated for high-power ballasts, with a withstand voltage of ≥220V.

Iv. Typical Application Circuit

textCopy Code

+Power Supply → C1 → PTC (Rt) → Filament → C2 → Resonant Circuit → High-Voltage Output

C1/C2: Coupling capacitors, working with the PTC to control preheating time.

V. Cost and Market

Price Range: 0.06-1.5 yuan/unit (depending on model and purchase quantity).

Mainstream Brands: Minzheng, Sanbao, usw., supplying international manufacturers such as Philips and GE.

Through appropriate selection, PTC thermistors can effectively solve the startup reliability issues of CFLs/ballasts and are key components in the energy-saving lighting industry.

Model List

| Modellspezifikationen | Curie-Temperatur | Zero-Power Resistance | Maximale Spannung | Abmessungen | |

| Tc(℃) | R25℃(Ω) | Vmax(V) | Dmax | Hmax | |

| SPMZA-4H151RN500 | 75±7 | 150±30 % | 500 | 4.5 | 5.0 |

| SPMZA-4H221RN600 | 220±30 % | 600 | 4.5 | 5.0 | |

| SPMZA-4H331RM650 | 330±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H401RN650 | 400±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H501RN650 | 500±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H651RN650 | 650±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H102RN650 | 1000±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H152RN650 | 1500±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H202RN650 | 2000±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H302RN650 | 3000±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4H502RN650 | 5000±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4M151RN500 | 105±7 | 150±30 % | 500 | 4.5 | 5.0 |

| SPMZA-4M221RN600 | 220±30 % | 600 | 4.5 | 5.0 | |

| SPMZA-4M331RM650 | 330±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4M401RN650 | 400±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4M501RN650 | 500±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4M651RN650 | 650±30 % | 600 | 4.5 | 5.0 | |

| SPMZA-4M102RN650 | 1000±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-4M152RN650 | 1500±30 % | 650 | 4.5 | 5.0 | |

| SPMZA-5I151M500 | 85±7 | 150±30 % | 500 | 5.5 | 5.0 |

| SPMZA-5I221M650 | 220±30 % | 650 | 5.5 | 5.0 | |

| SPMZA-5I331M650 | 330±30 % | 650 | 5.5 | 5.0 | |

| SPMZA-5I401M650 | 400±30 % | 650 | 5.5 | 5.0 | |

| SPMZA-5I651M650 | 650±30 % | 650 | 5.5 | 5.0 | |

| SPMZA-5I102M650 | 1000±30 % | 650 | 5.5 | 5.0 | |

| SPMZA-6H151RN600 | 75±7 | 150±30 % | 600 | 6.5 | 5.0 |

| SPMZA-6H221RN650 | 220±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H331RN650 | 330±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H401RN650 | 400±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H501RN650 | 500±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H651RN650 | 650±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H102RN650 | 1000±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6H152RN650 | 1500±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6M151RN600 | 105±7 | 150±30 % | 600 | 6.5 | 5.0 |

| SPMZA-6M221RN650 | 220±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6M331RN650 | 330±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-6M401RN650 | 400±30 % | 650 | 6.5 | 5.0 | |

| SPMZA-8H151RN650 | 75±7 | 150±30 % | 650 | 8.0 | 5.0 |

| SPMZA-8H221RN650 | 220±30 % | 650 | 8.0 | 5.0 | |

| SPMZA-8H331RN800 | 330±30 % | 800 | 8.0 | 5.0 | |

| SPMZA-8H401RN900 | 400±30 % | 900 | 8.0 | 5.0 | |

| SPMZA-9H151RN650 | 75±7 | 150±30 % | 650 | 9.0 | 5.0 |

| SPMZA-9H221RN650 | 220±30 % | 650 | 9.0 | 5.0 | |

| SPMZA-9H331RN800 | 330±30 % | 800 | 9.0 | 5.0 | |

| SPMZA-9H401RN900 | 400±30 % | 900 | 9.0 | 5.0 | |

Kontaktiere uns

Warten auf Ihre E-Mail, Wir werden Ihnen innerhalb von 24 Stunden antworten 12 Stunden mit wertvollen Informationen, die Sie brauchten.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt