Categorii de produse

- siguranță termica 32

- siguranțe de suprafață 12

- termistor 36

- Suport pentru siguranțe montat pe PCB 27

- Ham de cabluri 6

- Suporturi pentru siguranțe cu lame 17

- termostat 50

- Siguranta electrica 24

- Senzor de temperatură auto 7

- Întrerupător termic 22

- Suport cutie siguranțe 36

- Senzor de temperatura 75

- Comutator termic 68

- Siguranță auto 20

- Siguranțe înșurubate 8

Etichete de produs

Termistori PTC pentru lămpi și balasturi cu economie de energie

Termistorii PTC sunt utilizați în balasturile electronice și lămpile de economisire a energiei ca dispozitive de preîncălzire și pornire uşoară. Ele pot crește semnificativ numărul de cicluri și durata de viață a lămpilor. “Yaxun” a dedicat peste zece ani cercetării și producției de termistori PTC de preîncălzire și pornire uşoară, acumulând o vastă experiență. Aderarea la filozofia de afaceri a “Integritatea ca fundație, Inovația ca prioritate,” oferim clienților produse stabile și de încredere, câștigând încrederea clienților noștri. Termistorii noștri sunt utilizați de companii de iluminat electric de renume mondial, cum ar fi Philips, GE (China), IKEA, Megaman, Osram (China), și TCL. Cu producție anuală și vânzări depășind 100 milioane de unități, deținem o cotă de piață lider în rândul colegilor noștri atât pe plan intern, cât și pe plan internațional.

Termistorii PTC sunt utilizați în principal în lămpile de economisire a energiei și balasturile electronice pentru “preîncălziți pornirea soft” funcţie, îmbunătățind semnificativ durata de viață a lămpii și eficiența energetică. Următoarele sunt aplicațiile lor principale și punctele importante tehnice:

eu. Principiul de funcționare

Rece, Faza cu rezistență scăzută

Când circuitul este pornit, PTC este la temperatura camerei și are o rezistență scăzută (de ex., 30-60Oh). Curentul trece prin PTC pentru a preîncălzi filamentul (de obicei luând 0.4-2 secunde pentru a atinge o temperatură de funcționare de 1160K), împiedicând șocul direct de înaltă tensiune să provoace pulverizare și pierderea filamentului.

Fierbinte, Faza de înaltă rezistență

Când temperatura PTC atinge punctul Curie (de ex., 75°C-105°C), rezistența sa crește brusc (la câteva mii de ohmi). Curentul este deviat către circuitul rezonant, generând tensiune înaltă pentru a aprinde lampa, finalizarea procesului de pornire ușoară.

II. Avantajele de bază

Durată de viață extinsă a lămpii: Pornirea la preîncălzire mărește durata de viață a lămpii 4-5 ori.

Stres electric redus: Reduce impactul tensiunii ridicate bruște asupra componentelor electronice.

Auto-recuperare: Resetează automat după ce defecțiunea este rezolvată, eliminând necesitatea înlocuirii.

III. Parametri de selecție și exemple de model

| Parametrii | Valori/Interval tipice | Scenarii aplicabile |

|---|---|---|

| Rezistență la starea de echilibru | 30-300Oh | Rezistența scăzută reduce întârzierea la încălzire |

| Temperatura Curie | 75℃-105℃ | Compatibil cu lămpi de diferite puteri |

| Diametru | 4mm-12mm | Selectați în funcție de spațiul circuitului |

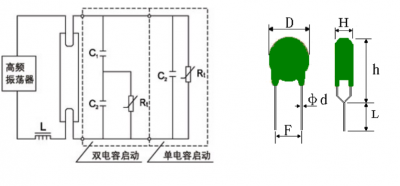

Diagrama aplicației

După cum se arată în figură: Când circuitul este conectat inițial, Rt este la temperatura camerei, rezistența sa mult mai mică decât cea a lui C2. Curentul trece prin C1, iar Rt formează un circuit pentru a preîncălzi filamentul. După aproximativ 0.4-2 secunde, Temperatura lui Rt depășește temperatura comutatorului, Miros, și intră într-o stare de înaltă rezistență. Rezistența sa este mult mai mare decât impedanța lui C2. Curentul care trece prin C1 și C2 formează o buclă, provocând rezonanță LC și generând tensiune înaltă, care luminează lampa.

Modele comune:

MZ4/MZ5: Potrivit pentru CFL-uri de putere mică și medie (18W-72W).

WMZ11A: Dedicat pentru balasturi de mare putere, cu o tensiune de rezistență ≥220V.

Iv. Circuit de aplicație tipic

textCopy Code

+Alimentare → C1 → PTC (Rt) → Filament → C2 → Circuit rezonant → Ieșire de înaltă tensiune

C1/C2: Condensatoare de cuplare, lucrul cu PTC pentru a controla timpul de preîncălzire.

V. Cost și piață

Gama de prețuri: 0.06-1.5 yuani/unitate (in functie de model si cantitatea achizitionata).

Mărci mainstream: Minzheng, Sanbao, etc., furnizând producători internaționali precum Philips și GE.

Prin selecție adecvată, Termistorii PTC pot rezolva în mod eficient problemele de fiabilitate la pornire ale CFL/balasturilor și sunt componente cheie în industria de iluminat cu economie de energie.

Lista de modele

| Specificațiile modelului | Temperatura Curie | Rezistență cu putere zero | Tensiune maximă | Dimensiuni | |

| Tc(℃) | R25℃(Ω) | Vmax(V) | Dmax | Hmax | |

| SPMZA-4H151RN500 | 75±7 | 150±30% | 500 | 4.5 | 5.0 |

| SPMZA-4H221RN600 | 220±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4H331RM650 | 330±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H401RN650 | 400±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H501RN650 | 500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H651RN650 | 650±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H102RN650 | 1000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H152RN650 | 1500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H202RN650 | 2000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H302RN650 | 3000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H502RN650 | 5000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M151RN500 | 105±7 | 150±30% | 500 | 4.5 | 5.0 |

| SPMZA-4M221RN600 | 220±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4M331RM650 | 330±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M401RN650 | 400±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M501RN650 | 500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M651RN650 | 650±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4M102RN650 | 1000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M152RN650 | 1500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-5I151M500 | 85±7 | 150±30% | 500 | 5.5 | 5.0 |

| SPMZA-5I221M650 | 220±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I331M650 | 330±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I401M650 | 400±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I651M650 | 650±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I102M650 | 1000±30% | 650 | 5.5 | 5.0 | |

| SPMZA-6H151RN600 | 75±7 | 150±30% | 600 | 6.5 | 5.0 |

| SPMZA-6H221RN650 | 220±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H331RN650 | 330±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H401RN650 | 400±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H501RN650 | 500±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H651RN650 | 650±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H102RN650 | 1000±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H152RN650 | 1500±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M151RN600 | 105±7 | 150±30% | 600 | 6.5 | 5.0 |

| SPMZA-6M221RN650 | 220±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M331RN650 | 330±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M401RN650 | 400±30% | 650 | 6.5 | 5.0 | |

| SPMZA-8H151RN650 | 75±7 | 150±30% | 650 | 8.0 | 5.0 |

| SPMZA-8H221RN650 | 220±30% | 650 | 8.0 | 5.0 | |

| SPMZA-8H331RN800 | 330±30% | 800 | 8.0 | 5.0 | |

| SPMZA-8H401RN900 | 400±30% | 900 | 8.0 | 5.0 | |

| SPMZA-9H151RN650 | 75±7 | 150±30% | 650 | 9.0 | 5.0 |

| SPMZA-9H221RN650 | 220±30% | 650 | 9.0 | 5.0 | |

| SPMZA-9H331RN800 | 330±30% | 800 | 9.0 | 5.0 | |

| SPMZA-9H401RN900 | 400±30% | 900 | 9.0 | 5.0 | |

Contactaţi-ne

Aștept e-mailul dvs, vă vom răspunde în termen 12 ore cu informații valoroase de care aveai nevoie.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt