Produktkategorier

- Termisk sikring 32

- Surface Mount sikringer 12

- termistor 36

- PCB Monter sikringsholder 27

- Ledningsnett 6

- Blade sikringsholdere 17

- termostat 50

- Elektrisk sikring 24

- Automotive temperatursensor 7

- Termisk effektbryter 22

- Sikringsboksholder 36

- Temperatursensor 75

- Termisk bryter 68

- Bil sikring 20

- Bolt ned sikringer 8

Produktkoder

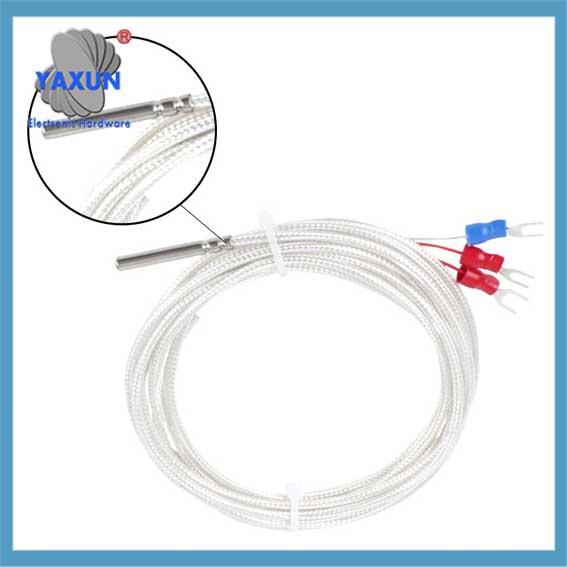

NTC, PTC, PT100, DS18B20 for temperatursondesensorer

Termoelementsonde: Den bruker den termoelektriske effekten til å måle temperatur, og har egenskapene til et bredt måleområde og rask responshastighet.

Termisk motstandssonde: bruker egenskapen at motstanden til metall eller halvledermaterialer endres med temperaturen for å måle temperatur, og har egenskapene til høy målenøyaktighet og god stabilitet.

Halvledersonde: bruker egenskapen at ledningsevnen til halvledermaterialer endres med temperaturen for å måle temperatur, og har egenskapene til liten størrelse, lav vekt og lavt strømforbruk.

NTC, PTC, PT100, DS18B20 Temperature probes and temperature sensors play an important role in the field of temperature measurement. The following is a detailed introduction to temperature probe sensors:

Det finnes mange typer temperatursensorer, including:

Termoelementer

These sensors are made of two dissimilar metals that connect at two points to form a junction. They are reliable, korrekt, and can operate over a wide range of temperatures.

Resistance temperature detectors (RTS)

These sensors are based on the change in resistance of a metal as the temperature changes.

Termistorer

These sensors use the temperature characteristics of semiconductor resistors, which change resistance as the temperature changes. Thermistors are sensitive and have high accuracy relative to their cost.

Negativ temperaturkoeffisient (NTC) termistorer

These sensors are sensitive and can respond to very small temperature changes. They have a temperature range of -50 °C til 250 ° C..

Resistive temperature detectors

These sensors have positive temperature coefficients (PTC) and offer precise temperature measurements. Imidlertid, they have poor sensitivity.

1. Definition and working principle

Temperature probe:

Definisjon: A temperature probe is a device specifically used to measure temperature, and its core component is a temperature-sensitive element.

Working principle: A temperature probe uses sensitive elements (som termoelementer, termiske motstander, halvledere, etc.) to convert temperature changes into electrical signals for subsequent circuit processing or display.

Temperature sensor:

Definisjon: A temperature sensor is a broader concept that includes a temperature probe and a signal processing circuit connected to it.

Working principle: A temperature sensor not only includes a sensitive element, but also has a signal processing circuit that can complete the acquisition, behandling og utgang av temperatursignaler, usually in the form of digital or analog signals.

2. Types and characteristics

Temperature probe type:

Termoelementsonde: Den bruker den termoelektriske effekten til å måle temperatur, og har egenskapene til et bredt måleområde og rask responshastighet.

Termisk motstandssonde: bruker egenskapen at motstanden til metall eller halvledermaterialer endres med temperaturen for å måle temperatur, og har egenskapene til høy målenøyaktighet og god stabilitet.

Halvledersonde: bruker egenskapen at ledningsevnen til halvledermaterialer endres med temperaturen for å måle temperatur, og har egenskapene til liten størrelse, lav vekt og lavt strømforbruk.

Temperature sensor type:

Analog temperature sensor: outputs analog signals, which need to be converted into digital signals by analog-to-digital converters for subsequent processing.

Digital temperature sensor: directly outputs digital signals, has strong anti-interference ability, høy nøyaktighet, and is easy to integrate into the control system.

Intelligent temperature sensor: has self-diagnosis, selvkalibrering, communication and other functions, og kan realisere fjernovervåking og kontroll.

3. Selection and application

Utvalgsfaktorer:

Application environment: Vurder om det målte miljøet har spesielle forhold som korrosivitet, høy temperatur, høyt trykk, etc., for å velge passende materialer og beskyttelsesnivåer.

Måleområde: Velg en passende sensor i henhold til området til temperaturen som skal måles for å sikre at sensoren kan måle nøyaktig innenfor det nødvendige området.

Accuracy requirements: According to the accuracy requirements of the application for temperature measurement, select a sensor with corresponding accuracy.

Cost budget: Under the premise of ensuring performance, consider cost factors and choose cost-effective sensors.

Application areas:

Industriell automasjon: used to monitor temperature changes in industrial equipment, machines and production processes to ensure normal operation of equipment and product quality.

Medical industry: used in medical equipment, temperature monitoring instruments and drug storage equipment to monitor patient temperature, omgivelsestemperatur og legemiddellagringsforhold.

Automotive industry: used in electric vehicle motors, kondensatorer, DC-omformere, ladesystemer, as well as automobile engines, girkasser, air conditioning systems and exhaust systems to monitor and control the temperature of various liquids and gases.

Agriculture and food processing industry: used in agricultural greenhouses, cold storage, food processing equipment and transport vehicles to monitor and control the temperature of agricultural products and food.

Other fields: such as air conditioning and refrigeration industry, military and aerospace industry, Internet of Things industry, osv. are also widely used.

IV. Use and maintenance

installasjon: Install the sensor correctly according to the installation instructions to ensure good contact between the sensor and the object to be measured and avoid measurement errors caused by improper installation.

Kabling: Koble signalledningen og strømledningen til sensoren riktig for å sikre stabiliteten og nøyaktigheten til signaloverføringen.

Kalibrering: Kalibrer sensoren regelmessig for å sikre at målenøyaktigheten oppfyller applikasjonskravene. The calibration process usually involves placing the sensor in a known temperature environment, comparing the difference between its output value and the standard value, and making necessary adjustments.

vedlikehold: Rengjør og vedlikehold sensoren regelmessig for å unngå støv, skitt, osv. that affect the measurement performance of the sensor. Samtidig, pay attention to check whether the cable connection is loose or damaged, and replace damaged parts in time.

Oppsummert, temperature probe sensors have a wide range of applications and an important position in the field of temperature measurement. When selecting and using them, it is necessary to make comprehensive considerations based on the specific application scenarios and requirements to ensure the accuracy and reliability of the measurement results. If you have any other questions or need further help, please feel free to let me know.

Kontakt oss

Venter på e -posten din, Vi vil svare deg innen 12 timer med verdifull informasjon du trengte.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt