製品カテゴリ

- 温度ヒューズ 32

- 表面実装ヒューズ 12

- サーミスター 36

- PCB マウント ヒューズ ホルダー 27

- ワイヤハーネス 6

- ブレードヒューズホルダー 17

- サーモスタット 50

- 電気ヒューズ 24

- 自動車温度センサー 7

- サーマルサーキットブレーカー 22

- ヒューズボックスホルダー 36

- 温度センサー 75

- サーマルスイッチ 68

- カーヒューズ 20

- ボルトダウンヒューズ 8

製品タグ

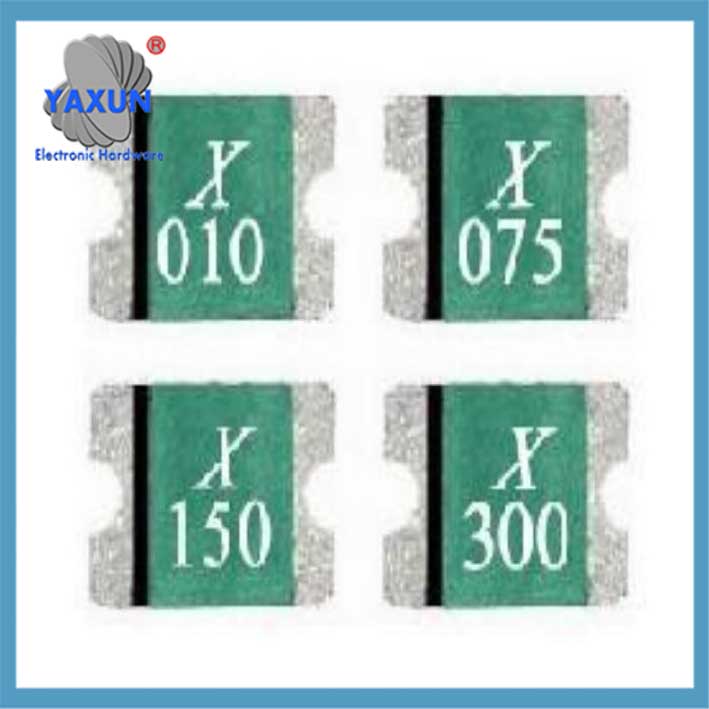

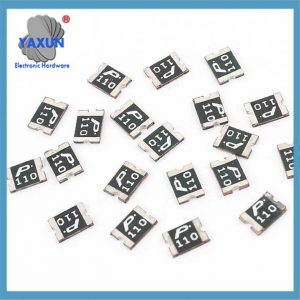

再セット可能なチップヒューズの関数とアプリケーション

リセッタブルチップヒューズ, PTCとしても知られています (正の温度係数) リセッタブルヒューズまたはPPTC (ポリマーの正の温度係数) デバイス, 障害状態が解消された後に自動的にリセットされる回路保護コンポーネントです. 過電流や過熱の状況から保護します。, さまざまなアプリケーションで信頼性を高め、ダウンタイムを削減する自己リセット ソリューションを提供します。.

リセッタブルチップヒューズ (PPTC) are overcurrent protection components based on the positive temperature coefficient characteristics of polymers. They have an automatic reset function and are widely used in circuit protection of electronic equipment. 以下はそのコアポイントです:

1. 構造と動作原理

材料構成

It is composed of specially treated polymer resins (such as PE polymers) と導電性粒子 (カーボンブラックまたは金属粒子). 通常の条件下, 導電性粒子が低抵抗パスを形成 (0.1-数オーム). Protection mechanism

過電流が発生した場合, 電流の熱効果により樹脂が溶けて膨張します。, the conductive network to break, and the resistance suddenly increases to a high-resistance state (up to megohms), limiting the current to microamperes. After the fault is resolved, 導電性粒子が冷えて収縮する, 再接続する, and restore the low-resistance state without manual replacement.

過電流保護:

Resettable fuses limit excessive current flow in a circuit, preventing damage to sensitive components during short circuits or overload conditions.

Over-temperature Protection:

They can also sense and respond to excessive temperatures, tripping to a high-resistance state to prevent overheating and potential damage.

自己リセット:

従来のヒューズとは異なります, resettable fuses automatically return to their low-resistance state once the fault condition is removed and the temperature or current drops below the trigger point.

2. Key parameters and characteristics

| パラメーター | 説明 |

|---|---|

| Holding current | Maximum current to maintain non-action (例えば. 0.05-3A for 0805 パッケージ) |

| Action current | Minimum steady-state current to trigger protection (いつもの 2 times the holding current) |

| Withstand voltage | Typical value 16-60V, the withstand voltage value will decrease at high temperature |

| Response time | Overload can be triggered in milliseconds, which is related to the current overload multiple |

3. 典型的なアプリケーションシナリオ

家電:

Widely used in smartphones, ラップトップ, テレビ, and other electronic devices to protect against overcurrents and over-temperature issues.

Power Supplies:

Provide reliable protection for power supplies in various devices and systems, preventing damage from short circuits or excessive current draw.

カーエレクトロニクス:

Used in cars for protecting dashboard electronics, control modules, and entertainment systems from overcurrents.

Telecommunications:

Protects routers, スイッチ, and other communication devices from damage caused by overcurrents, ensuring uninterrupted connectivity.

Industrial Control Systems:

Safeguard electronic control panels, PLC (Programmable Logic Controllers), and other critical components in industrial settings.

Aerospace and Nuclear Applications:

Provide reliable protection in environments where fuse replacement is difficult or impractical.

Medical Devices:

Can be found in some medical devices, ensuring the safety and reliability of critical medical equipment.

Audio Systems:

Protects loudspeakers, especially tweeters, from damage due to overdriving.

4. 選択に関する考慮事項

電流マッチング: The maintenance current should be 1.25 times higher than the maximum operating current of the circuit;

Package selection: Select 0402/0603 and other sizes according to the PCB space, そして 1812/2920 packaging is required for high current scenarios;

environmental adaptability: The current usage needs to be reduced in high temperature environments to avoid false triggering.

5. Technology development trends

Material optimization: New nano-composite materials improve response speed and pressure resistance.

Structural innovation: 例えば, YAXUN Electronics’ adjustable patch components are suitable for different circuit layouts.

If you need a test standard, you can refer to the 25°C environment to verify the maintenance current (no action for 15 分) and action current (trigger within 5 分) and other indicators.

Advantages over traditional fuses:

自己リセット:

Eliminates the need for manual fuse replacement, reducing downtime and maintenance costs.

コンパクトなサイズ:

Resettable fuses are often smaller than traditional fuses, making them easier to integrate into compact electronic devices.

Longer Lifespan:

Capable of withstanding numerous overcurrent events, leading to a longer overall lifespan compared to traditional fuses.

No Arcing:

Resettable fuses do not produce sparks or arcing during a fault, enhancing safety.

お問い合わせ

メールを待っています, 以内に返信させていただきます 12 必要な貴重な情報を何時間も入手できる.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt