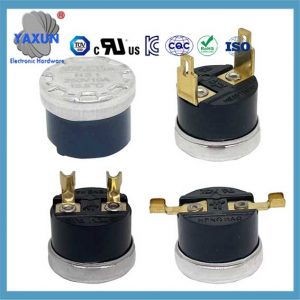

China custom bimetallic thermal disc cutoff switch has surface mount and PCB plug-in installation. Overheat circuit cutoffs switch (bimetal thermostat) adalah perangkat yang dirancang untuk menjaga komponen tetap aman dalam situasi ketika terjadi suhu berlebihan. List of Select Surface Mount Thermal Switches and thermal protectors product Specs, datasheets, manufacturers & suppliers.

Surface Mount Bimetal disc Thermal Switch are indispensable components in the safe and efficient operation of motors/ Electrical appliances. Dengan mencegah overheating, they protect Electrical appliancesfrom damage, memperpanjang umur operasionalnya, mengurangi risiko bahaya kebakaran, memastikan pengoperasian yang aman, dan meminimalkan downtime dan biaya pemeliharaan. Lebih-lebih lagi, Bimetal disc thermal switch help in complying with industry safety standards, memberikan ketenangan pikiran kepada operator dan pemangku kepentingan. Seiring kemajuan teknologi, thermal switch continue to evolve, menawarkan perlindungan yang lebih tepat dan andal untuk motor dalam berbagai aplikasi.

Dengan berkembangnya teknologi, jangkauan aplikasi motor semakin luas, terutama penggunaan motor dalam kehidupan sehari-hari dan produksi juga semakin penting. Namun kecelakaan motor terbakar juga terjadi, dalam kehidupan nyata, motor terbakar terutama disebabkan oleh panas berlebih pada kumparan yang tersumbat berikut ini, beban motor terlalu besar kelebihan beban, kurangnya fase dan alasan lainnya. Installing a heat protector is one of the effective ways to protect the motor. sakelar termal, juga disebut saklar suhu, saklar pengatur suhu, dll.. Ini adalah sejenis saklar suhu dengan lembaran bimetal sebagai elemen penginderaan suhu, ketika alat listrik bekerja normal, lembaran bimetal berada dalam keadaan bebas, kontaknya dalam keadaan terputus, ketika suhu naik ke nilai suhu aksi, elemen bimetal dipanaskan untuk menghasilkan tegangan internal dan aksi cepat, buka kontaknya, memutus/menyambungkan rangkaian, so as to play a bimetal thermal switch role. Wait until the ambient temperature drops to thereset temperature of the protector, kontak akan menutup kembali sirkuit yang terhubung, dan motor akan bekerja kembali.

Choosing The Right thermal switch

How to choose the right circuit Off bimetal disc switch is very important, jika tidak, bukan hanya tidak bisa memainkan peran protektif, namun akan menyebabkan motor tidak dapat bekerja karena salah pemilihan, atau bahkan terbakar.

1. Voltase & Penentuan saat ini

• Bimetal disc thermal switch have different voltage ranges 400V 380V 230V 220V 110V, DC motors will also have 36V 24V 12V, dll., according to different working voltages to choose different rated voltage protectors, pada prinsipnya, tegangan aplikasi sebenarnya kurang dari atau sama dengan tegangan pengenal pelindung, Misalnya, 380V motor cannot choose rated voltage 220V protector, dan pelindung tegangan pengenal 220V dapat digunakan pada motor 110V;

• The current of the electrical appliances motors is divided into three kinds of starting current, arus kerja normal dan arus diblokir, the rated current of the protector should be greater than the maximum value of the three currents, dan perlu meninggalkan margin. Misalnya, motor bekerja normal saat ini 1A, mulai saat ini 1.5A, memblokir arus 2A, then the rated current of the selected protector is at least 2A, dan yang terbaik adalah memilih arus pengenal 3A atau 5A untuk mempertahankan margin. Some motor starting current is greater than the rated current of the protector, tetapi waktu mulainya lebih singkat, dan arus kerja normal dan arus pemblokiran kurang dari arus pengenal pelindung, dalam hal ini, Anda juga dapat memilih pelindung ini. Karena arus awal lebih besar dari arus pengenal, tapi karena waktunya singkat, the thermal effect of the current has not had time to make the double piece heat leading to protection of the protector, agar tidak menimbulkan kesalahan.

2. Choose to thermal switch the temperature

• The choice of thermal switch temperature is related to three factors: insulation level of enameled wire, installation position and protector type.

The thermal switch temperature is lower than the maximum allowable temperature, Misalnya, the maximum temperature ofF class is 155℃, and the actual selection can be 145℃ or 150℃.

•The installation position is divided into built-in inside the coil and bundled outside the coil, because when the motor is blocked and forwarded heat, the overheating phenomenon spreads from inside and outside. If the protector is buried in the interior, the thermal switch temperature is slightly lower than the highest temperature of the enamelled wire; If it is tied outside the coil, consider the temperature difference between the inside and outside, and choose a lower temperature protector. Misalnya, the insulation level is F class enameled wire, coil inside and outside the temperature difference of 20℃, then choose 155-20=135℃ or so of the protector;

Motor protector has protection functions such as overload, kegagalan fase, imbalance, underload, grounding/leakage, dan kios. It can form a motor control protection unit with electrical components such as contactors and motor starters. It has functions such as remote automatic control, on-site direct control, panel indication, signal alarm, and field bus communication.

3. Selection of the thermal switch life

Different motor lock-in test time different requirements for the life of the protector are not the same, such as normal household motor lock-in 18 hari, the number of cycles of normal action reset will not exceed 100000 kali, the rated voltage current life of more than 100000 times can be selected protector; Some pump motors only do 3 days of blocking, pada prinsipnya, the life requirement is hundreds of times.

4. Selection of the thermal switch for sealing performance

Motor coil in the thermal switch process will dip paint to enhance the insulation performance of the process, dip paint is divided into drop paint, pencelupan, vacuum into the paint and other processes, especially the vacuum into the paint pressure is large, insulating paint is easy to enter the inside of the protector, resulting in the failure of the protector. The ST01 series of An Electronics has a very high sealing, under the condition of -0.08anggota parlemen, the paint dipping rate can reach 3%; In the case of -0.03anggota parlemen, the paint rate can reach less than one in ten thousand.

Motor protector parameters

| Parameter teknis

Auxiliary power supply |

Technical indicators | |||

| ARD2(L) | ARD2F | ARD3 | ||

| Auxiliary power supply | Voltase | AC85V~265V/DC100V~350V | ||

| Voltase | ≤7VA | ≤15VA | ||

| Rated working voltage | AC380V/AC660V,50Hz/60Hz | |||

| Rated operating current | 1A(0.1~9999) | |||

| 5A(0.1~9999) | ||||

| 1.6A(0.4A~1.6A) | ||||

| 6.3A(1.6A~6.3A) | ||||

| 25A(6.3A~25A) | ||||

| 100A(25A~100A) | ||||

| 250A(63A~250A) | ||||

| 800A(250A~800A) | ||||

| Relay output contact capacity | AC250V/ 3A;DC30V/ 3A | AC250V/ 6A | ||

| Switch input | 2-way | 9-way | ||

| Environment | Suhu kerja: -10°C~55°C | |||

| Suhu penyimpanan: -20°C~65°C | ||||

| Relative humidity: 5﹪~95﹪ without condensation | ||||

| Altitude: ≤ 2000m | ||||

| Pollution level | 2 | |||

| Tingkat perlindungan | IP20 | Main unit IP20 Display unit IP45 | ||

| Installation category | Level III | |||

Bimetal motor protector

| Parameter teknis | Technical indicators | ||

| ARD3T auxiliary power supply | AC/DC 110 / 220V or AC 380V,power consumption≤15VA | ||

| Motor rated working voltage | AC 380V / 660V,50Hz / 60Hz | ||

| Motor rated working current | 1.6(0.40A-2.00A) | Measured using measurement module | |

| 6.3(1.6A-6.3A) | |||

| 25(6.3A-25A) | |||

| 100(25A-100A) | |||

| 250(63A-250A) | Using external current transformer + measurement module | ||

| 800(250A-800A) | |||

| Kebocoran arus | 50mA-1A | Using measurement module + leakage current transformer | |

| 3A-30A | |||

| Relay output contact capacity | Beban resistif | AC250V、6A;DC24V、6A | |

| Inductive load | AC250V、2A;DC24V、2A | ||

| Main switch input and output | 4DI、4DO,DI Can be dry or wet node | ||

| Switch module | 4DI、3DO,DI Can be dry or wet node | ||

| Temperature module | External sensor type:PT100、PT1000、Cu50、PTC、NTC

Number of sensor channels: 3 Corresponding measurement range of sensor: PT100/PT1000:-50°C~+500°C Cu50:-50°C~+150°C PTC/NTC:100Ω~30kΩ |

||

| Analog module | Can be realized: 2-way 4~20mA input measurement, 2-way 4~20mA transmission output

4~20mA input measurement accuracy ±0.5% 4~20mA output maximum load capacity is ≤500Ω |

||

| Main communication | RS485:Modbus-RTU | ||

| Communication module | RS485:Dual Modbus-RTU、Profibus | ||

| Environment | Suhu kerja | -10ºC~55ºC | |

| Suhu penyimpanan | -25ºC~65ºC | ||

| Relative humidity | ≤95﹪No condensation, no corrosive gas | ||

| Altitude | ≤2000m | ||

| Pollution level | Level 3 | ||

| Tingkat perlindungan | Main body IP20, split display module IP45 (installed on the cabinet) | ||

| Installation category | Level III | ||

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt