Az alapvető különbség a gyors és a lassú működésű biztosítékok között. Fő különbségeik az olvadás sebességében és az impulzusáramoknak való ellenálló képességben rejlenek. A gyorsan működő biztosítékok gyorsan reagálnak, és alkalmasak az érzékeny áramkörök védelmére; A lassú működésű biztosítékok ellenállnak a pillanatnyi túlfeszültségnek, és elkerülhetik a hamis kioldást.

Az alkalmazási forgatókönyvekkel kapcsolatban, megemlítik, hogy a gyors működésű biztosítékok ellenállásos terhelésekre és IC védelemre alkalmasak, míg a lassú működésű biztosítékok kapacitív/induktív terhelésekre alkalmasak. Ez az információ nagyon fontos, mert a rossz alkalmazási forgatókönyv miatt az eszköz nem indul el, vagy a védelem meghiúsul. Különösen hangsúlyozni kell, hogy lassú működésű biztosítékokat kell használni túlfeszültség esetén, például kapcsolóüzemű tápegységeknél..

Technikai elveket tekintve, a “késleltetési jellemzők” A lassú működésű biztosítékok speciális szerkezetekből és anyagkialakításokból származnak, amelyek lehetővé teszik számukra az energia elnyelését és az impulzusok ellenállását. Ez az elvi magyarázat nagyon értékes, és segíthet a felhasználóknak megérteni, hogy a gyors működésű biztosítékok miért nem helyettesíthetik egyszerűen a lassú működésű biztosítékokat.

Gyakorlati javaslatok a paraméterválasztáshoz: A névleges áramerősség a 1.5-2 a munkaáram szorzata. Viszont, fontos megjegyezni azt a félreértést, hogy minél gyorsabb a cselekvés, annál jobb. A “lomhaság” A lassú működésű biztosítékok valójában az intelligens ítélőképességük tükröződése.

Világosabb lenne, ha megfontolandó lenne, ha táblázatba rendezné az összehasonlítást. A táblázatnak négy dimenziót kell tartalmaznia: fúziós jellemzők, alkalmazható terhelések, tipikus alkalmazások, és helyettesítési elvek, hogy a felhasználók egy pillantással láthassák. Például, a “túlfeszültség ellenállás” egy lassan kiolvadó biztosíték kapacitív/induktív terhelésnek felel meg, és tipikus alkalmazások a kapcsolóüzemű tápegységek és a motorindítás.

A fő különbség a gyors hatású (gyors ütés) és lassú hatású (lassú ütés) A biztosítékok a biztosíték jellemzőiben rejlenek, alkalmazási forgatókönyvek és túlfeszültség-ellenállás. A konkrét összehasonlítás a következő:

én. Alapvető különbség

| Jellemzők | Gyorsan működő biztosíték | Lassú működésű biztosíték |

|---|---|---|

| Beégetési sebesség | Gyors válasz, gyors beolvadás túláram esetén (ezredmásodperces szint) | Válasz késése, rövid impulzusáramot képes ellenállni a biztosítékolás előtt |

| Túlfeszültség ellenállás | Gyenge, könnyen tévedésből felfújja a pillanatnyi nagy áram | Erős, képes elnyelni az energiát, hogy ellenálljon a túlfeszültségnek |

| Alkalmazható terhelési típus | Ellenállási terhelés (mint például a fűtőszál), érzékeny IC áramkör | Kapacitív/induktív terhelés (mint például a motor, kapcsolóüzemű tápegység) |

II.. Alkalmazási forgatókönyv

Gyors működésű biztosíték alkalmazható forgatókönyv

Ellenállásos áramkör stabil üzemi árammal (elektromos vízforraló, fűtőtest);

Áramkör, amelynek gyorsan meg kell védenie az értékes eszközöket (IC, MOS cső);

Érzékeny elektronikus berendezés túlfeszültség nélkül.

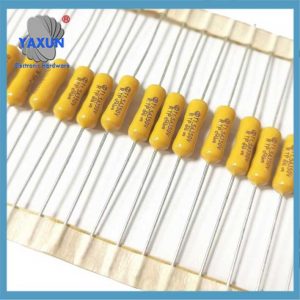

Lassan kiolvadó biztosíték alkalmazási forgatókönyvei

Kapacitív áramkörök indítási túlfeszültségekkel (kapcsolóüzemű tápegység elektrolitkondenzátorainak töltése);

Induktív terhelések nagy indítási áramokkal (motorok, kompresszorok);

Táp bemeneti/kimeneti csatlakozók és egyéb impulzusinterferenciára érzékeny kapcsolatok.

III. Kiválasztási szempontok

Névleges áram: Általában 1.5-2 a berendezés maximális üzemi áramának szorzata, hogy kompatibilis legyen a túlfeszültségekkel.

A csere elve:

A Fast-break helyettesíthető lassú szünettel az interferencia elleni küzdelem javítása érdekében (kivéve az érzékeny áramköröket);

Soha ne cserélje le a lassú szünetet gyors szünetre, ellenkező esetben indítási biztosítékot okoz (például amikor a motor beindul).

A megkülönböztetés jelölése:

A gyors szünetet általában az F betű jelöli (Gyors hatású), a lassú szünetet pedig T jelöli (Idő-késleltetés).

IV. Műszaki elv

Lassú szünet késleltetési mechanizmus: Speciális struktúrákon keresztül nyelje el az energiát (mint például az ötvözetolvadékok), átmenetileg ellenáll az impulzusáramoknak (mint például a kondenzátor töltőáramok), és csak folyamatos túlterhelés esetén biztosítékot.

Gyors megszakítási mechanizmus: A biztosíték finom szerkezetű és érzékeny az áramváltozásokra, túláram esetén azonnal megszakad.

⚠️ Félreértés javítása: A lassú szünet nem azt jelenti “lassú válasz”, de megkülönböztetheti a hibás áramot és az impulzusáramot a hamis védelem elkerülése érdekében.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt