Kategorije proizvoda

- toplinski osigurač 32

- osigurači površinskih nosača 12

- termistor 36

- Držač osigurača za PCB 27

- Kabelski svežanj 6

- Držači osigurača noža 17

- termostat 50

- Električni osigurač 24

- Senzor automobilske temperature 7

- Toplinski prekidač 22

- Držač kutije s osiguračima 36

- Senzor temperature 75

- Toplinski prekidač 68

- Osigurač automobila 20

- Osigurači 8

Oznake proizvoda

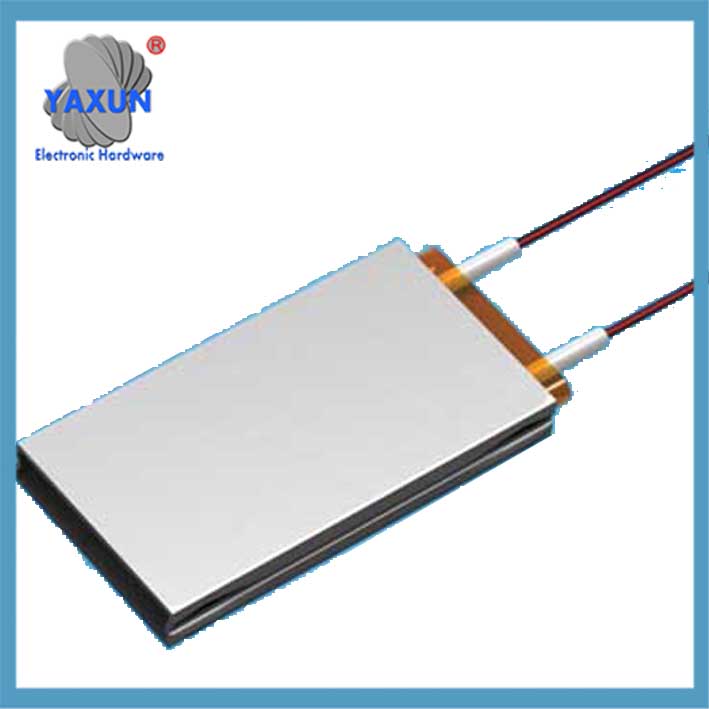

PTC termistori za grijanje pri konstantnoj temperaturi

PTC grijači konstantne temperature su uređaji za grijanje dizajnirani za korištenje karakteristika grijanja konstantne temperature PTC termistora. U niskom- i primjene grijanja srednje snage, PTC grijači nude prednosti u odnosu na tradicionalne grijaće elemente, kao što je zagrijavanje konstantne temperature, bez otvorenog plamena, visoka učinkovitost pretvorbe topline, minimalan utjecaj napona napajanja, i dug životni vijek. R. sve više daje prednost njihovoj upotrebi u električnim grijačima&D inženjeri.

Pregled proizvoda

The constant temperature heating characteristics of PTC thermistors for constant temperature heating are determined by the material properties. The principle is that when power is applied to the PTC thermistor, self-heating causes the component’s temperature to rise, causing the resistance value to enter the transition region and the current to drop rapidly. Consequently, the surface temperature of the PTC thermistor remains constant. This temperature is dependent solely on the PTC thermistor’s Curie temperature and the applied voltage, and is largely independent of the ambient temperature.

PTC grijači konstantne temperature su uređaji za grijanje dizajnirani za korištenje karakteristika grijanja konstantne temperature PTC termistora. U niskom- i primjene grijanja srednje snage, PTC grijači nude prednosti u odnosu na tradicionalne grijaće elemente, kao što je zagrijavanje konstantne temperature, bez otvorenog plamena, visoka učinkovitost pretvorbe topline, minimalan utjecaj napona napajanja, i dug životni vijek. R. sve više daje prednost njihovoj upotrebi u električnim grijačima&D inženjeri.

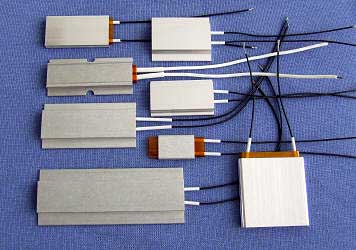

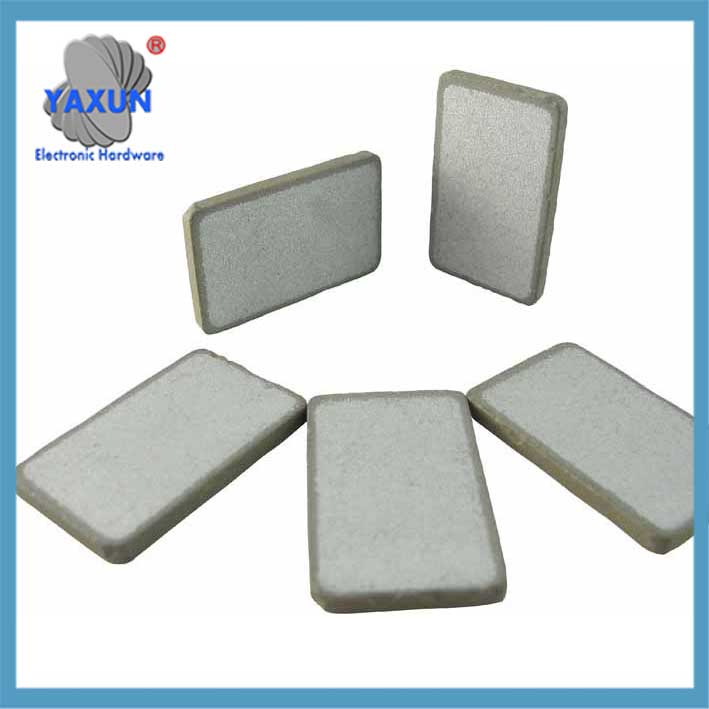

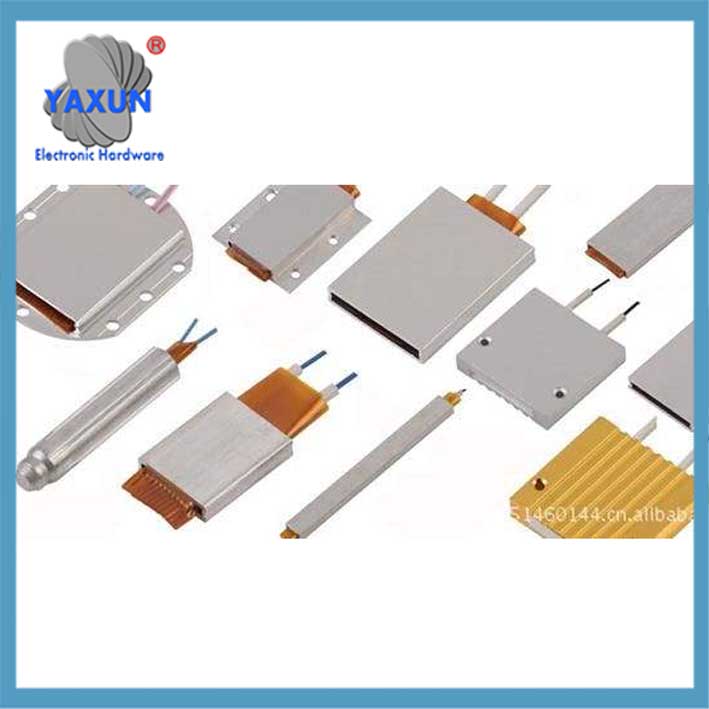

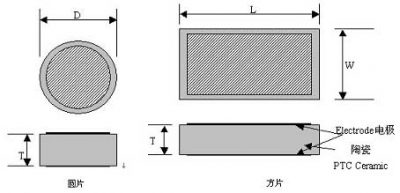

PTC thermistors for constant temperature heating can be manufactured in a variety of shapes and specifications. Common shapes include discs, rectangles, strips, rings, and honeycomb pores. Combining the above-mentioned PTC heating elements with metal components can create various high-power PTC heaters.

Application Design

Utilizing the constant-temperature heating principle of PTC thermistors, these devices can be designed for applications such as hair straighteners, hair clips, hair clips, perms, perms, ceramic perms, hvataljke za kosu, curling irons, electric combs, negative ion hair curlers, masažeri, mosquito repellents, mosquito repellents, mosquito coil dispensers, fragrance dispensers, perfume dispensers, hot melt glue guns, heated foot baths, strojevi za kaširanje, thermos cups, water boilers, strojevi za kavu, coffee warmers, coffee heaters, aparati za vodu, hot and cold water dispensers, milk heaters, bojleri, shower heaters, electric mosquito repellents, hand warmers, sušilice, electric hot plates, električna glačala, električna lemila, electric thermal adhesives, curling irons, showers, fan heaters, drying rooms, električni grijači, električni grijači, air conditioning systems, air conditioning heating systems, space heaters, air heating systems, hot water kettles, Sušilice za cipele, shoe drying devices, grijači za noge, električne grijaće ploče, analizatori spektra, spektralna terapija, uređaji za fizikalnu terapiju, infracrveno grijanje, sušilice rublja, karburatori za motocikle, električni ovlaživači zraka, grijanje otporno na vlagu za električne instrumente, small crystal device constant temperature baths, inkubatori konstantne temperature, elektronske termos boce, insulated boxes, insulated cups, insulated trays, insulated cabinets, insulated tables, električne grijaće ploče, uređaji za toplinsku terapiju, aparati za toplu kavu, tretmani ljepote parom, topilice voska, generatori pare, ovlaživači zraka, ovlaživači zraka, ekstruderi za čokoladu, hot packs, električna lemila, akupunktura, urinary catheters, grijači za noge, sušila za ruke, strojevi za šećernu vunu, masažeri, liquefied gas cylinder heating, mali grijači toplog zraka, sušila za kosu, grijači prostorija, sušilice, suhi ormari, sušilice rublja, industrijska oprema za sušenje, Electric dust collector hopper heater, train locomotive electric heater, grijanje kalupa, grijanje upravljačkog ormara otporan na vlagu, monitor otporan na vlagu, električna pećnica, električni toster, infusion box, medicinska oprema, kućanskih aparata, dnevni aparati, male kućanske aparate…itd.

Model Parameters

| Ring Temperature Resistance 25℃/Ω |

Surface Temperature /℃ |

Maksimalni napon /V |

Promjer D/mm |

Duljina L/mm |

Širina W/mm |

Debljina T/mm |

| 500~1500 | 50 | 270 | 8 | 3 | ||

| 300~800 | 85 | 140 | 16 | 11 | 2.5 | |

| 150~400 | 90 | 140 | 16 | 11 | 2.5 | |

| 600~1500 | 100 | 270 | 20 | 2.5 | ||

| 500~1500 | 110 | 270 | 16 | 11 | 2.2 | |

| 500~1500 | 130 | 270 | 20 | 2.2 | ||

| 200~800 | 150 | 140 | 10.8 | 2.2 | ||

| 200~800 | 155 | 270 | 10.8 | 2.2 | ||

| 500~1500 | 155 | 270 | 10.8 | 2.2 | ||

| 1.5~5K | 170 | 140 | 5 | 4 | 1.6 | |

| 150~500 | 175 | 140 | 10.8 | 2.2 | ||

| 500~1500 | 180 | 270 | 10.8 | 2.2 | ||

| 200~800 | 185 | 270 | 10.8 | 2.2 | ||

| 1~3K | 195 | 270 | 8 | 2.5 | ||

| 800~2K | 230 | 270 | 19 | 12 | 2.2 | |

| 800~2K | 250 | 270 | 13 | 2.5 | ||

| 2~5K | 250 | 270 | 20 | 2.5 | ||

| 300~1K | 250 | 140 | 23.5 | 10 | 2.2 | |

| 800~2K | 255 | 270 | 23.5 | 10 | 2.2 | |

| 500~2K | 275 | 270 | 35 | 10 | 2.1 | |

| 300~800 | 280 | 140 | 24 | 15 | 2.5 | |

| 0.8~3,5 tisuća | 280 | 270 | 24 | 15 | 2.5 |

Napomene o korištenju

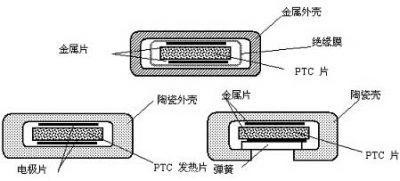

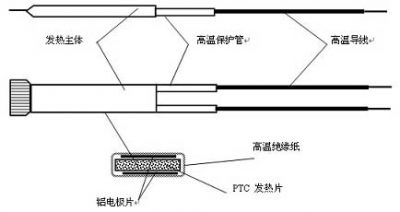

1) The PTC heater features automatic constant temperature control, eliminating the need for a temperature control system. It is the core component of all PTC heaters.

2) Four electrode types are available: electroless nickel + srebro, melt-blown aluminum, printed aluminum + srebro, and printed aluminum.

3) The operating voltage range is very wide. Even with a 2x increase in operating voltage, the surface temperature changes minimally.

4) When multiple PTC heaters are used together, treba ih spojiti paralelno, ne u seriji.

5) This product does not have lead wires or insulation. If this is not feasible, please select a model with an external insulation film or a metal housing.

Model Parameters

| Duljina/mm | Širina/mm | Debljina/mm | Surface Temperature/℃ | Insulation Withstand Voltage/V | Operating Voltage/V |

| 30~120 | 20 | 5.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 30 | 6.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 33 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 35 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 40 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 43 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 46 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 56 | 7.0 | 60~280 | 3750 | 100~240 |

Temperatures can be designed between 60°C and 280°C, and operating voltages can be designed between 12V and 240V, depending on customer requirements.

Usage Precautions

1) After power is applied, the heating power decreases gradually and then stabilizes. Stable power depends on operating conditions. The power of the same PTC heater can vary several times depending on operating conditions. Što je brže odvođenje topline, veća je stabilna snaga; the higher the PTC surface temperature, veća je snaga.

2) The surface temperature of the PTC heater is controlled by the PTC itself and can be controlled by disconnecting the circuit, but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) When using multiple PTCs, treba ih spojiti paralelno, ne u seriji.

Model Parameters

| Duljina (mm) | Širina (mm) | Debljina (mm) | Surface Temperature (° C) | Insulation Withstand Voltage (V) | Operating Voltage (V) |

| 24 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 24 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 above | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

Temperatures can be designed between 50°C and 280°C, and operating voltages can be designed between 3V and 240V, depending on customer requirements.

Usage Precautions

1) After power is applied, the heating power decreases gradually and then stabilizes. Stable power depends on operating conditions. The power of the same PTC heater can vary several times depending on operating conditions. Što je brže odvođenje topline, veća je stabilna snaga; the higher the PTC surface temperature, veća je snaga.

2) The surface temperature of the PTC heater is controlled by the PTC itself and can be controlled by disconnecting the circuit, but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) When using multiple PTCs, treba ih spojiti paralelno, ne u seriji.

Kontaktirajte nas

Čekajući vašu e -poštu, Odgovorit ćemo vam u okviru 12 sati s vrijednim informacijama koje su vam potrebne.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt