catégories de produits

- fusion thermique 32

- fusibles à montage en surface 12

- thermistance 36

- Porte-fusible à montage sur circuit imprimé 27

- Faisceau de câblage 6

- Porte-fusibles à lame 17

- thermostat 50

- Fusible électrique 24

- Capteur de température automobile 7

- Disjoncteur thermique 22

- Porte-boîte à fusibles 36

- Capteur de température 75

- Interrupteur thermique 68

- Fusible de voiture 20

- Fusibles boulonnés 8

Mots clés du produit

Thermistances PTC pour lampes et ballasts à économie d'énergie

Les thermistances PTC sont utilisées dans les ballasts électroniques et les lampes à économie d'énergie comme dispositifs de préchauffage et de démarrage progressif.. Ils peuvent augmenter considérablement le nombre de cycles et la durée de vie des lampes. “YAXUN” a consacré plus de dix ans à la recherche et à la production de thermistances PTC de préchauffage et de démarrage progressif, accumuler une vaste expérience. Adhérant à la philosophie d'entreprise de “L'intégrité comme fondement, L'innovation comme priorité,” nous fournissons aux clients des produits stables et fiables, gagner la confiance de nos clients. Nos thermistances sont utilisées par des sociétés d'éclairage électrique de renommée mondiale telles que Philips, GE (Chine), IKEA, Mégaman, Osram (Chine), et TCL. Avec une production et des ventes annuelles dépassant 100 millions d'unités, nous détenons une part de marché de premier plan parmi nos pairs, tant au niveau national qu'international.

Les thermistances PTC sont principalement utilisées dans les lampes à économie d'énergie et les ballasts électroniques pour le “préchauffer le démarrage progressif” fonction, améliorant considérablement la durée de vie de la lampe et l'efficacité énergétique. Voici leurs principales applications et points forts techniques:

je. Principe de fonctionnement

Froid, Phase de faible résistance

Au démarrage du circuit, le PTC est à température ambiante et a une faible résistance (par ex., 30-60Oh). Le courant circule à travers le PTC pour préchauffer le filament (prenant généralement 0.4-2 secondes pour atteindre une température de fonctionnement de 1160K), empêchant les chocs directs à haute tension de provoquer des pulvérisations et des pertes de filament.

Chaud, Phase haute résistance

Lorsque la température PTC atteint le point de Curie (par ex., 75°C-105°C), sa résistance augmente soudainement (à plusieurs milliers d'ohms). Le courant est détourné vers le circuit résonnant, générer de la haute tension pour allumer la lampe, terminer le processus de démarrage progressif.

II. Avantages principaux

Durée de vie prolongée de la lampe: Le démarrage par préchauffage augmente la durée de vie de la lampe de 4-5 fois.

Contrainte électrique réduite: Réduit l'impact d'une haute tension soudaine sur les composants électroniques.

Auto-récupération: Se réinitialise automatiquement une fois le défaut résolu, éliminant le besoin de remplacement.

III. Paramètres de sélection et exemples de modèles

| Paramètres | Valeurs/plage typiques | Scénarios applicables |

|---|---|---|

| Résistance à l’état d’équilibre | 30-300Oh | Une faible résistance réduit le délai de préchauffage |

| Curie Température | 75℃-105℃ | Compatible avec des lampes de différentes puissances |

| Diamètre | 4mm-12mm | Sélectionnez en fonction de l'espace du circuit |

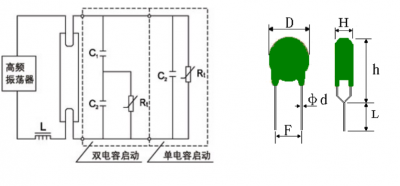

Diagramme d'application

Comme le montre la figure: Lorsque le circuit est initialement connecté, Rt est à température ambiante, sa résistance bien inférieure à celle du C2. Le courant traverse C1, et Rt forme un circuit pour préchauffer le filament. Après environ 0.4-2 secondes, La température de Rt dépasse la température du commutateur, Odeur, et entre dans un état de haute résistance. Sa résistance est bien supérieure à l'impédance de C2. Le courant circulant à travers C1 et C2 forme une boucle, provoquant une résonance LC et générant une haute tension, qui éclaire la lampe.

Modèles courants:

MZ4/MZ5: Convient aux LFC de petite et moyenne puissance (18W-72W).

WMZ11A: Dédié aux ballasts de forte puissance, avec une tension de tenue de ≥220V.

Iv. Circuit d'application typique

texteCopier le code

+Alimentation → C1 → PTC (RT) → Filament → C2 → Circuit résonant → Sortie haute tension

C1/C2: Condensateurs de couplage, travailler avec le PTC pour contrôler le temps de préchauffage.

V. Coût et marché

Gamme de prix: 0.06-1.5 yuans/unité (selon le modèle et la quantité achetée).

Marques grand public: Minzheng, Sanbao, etc., fournir des fabricants internationaux tels que Philips et GE.

Grâce à une sélection appropriée, Les thermistances PTC peuvent résoudre efficacement les problèmes de fiabilité de démarrage des LFC/ballasts et constituent des composants clés dans l'industrie de l'éclairage à économie d'énergie..

Liste des modèles

| Spécifications du modèle | Curie Température | Résistance à puissance nulle | Tension maximale | Dimensions | |

| Tc(℃) | R25℃(Ω) | Vmax(V) | Dmax | Hmax | |

| SPMZA-4H151RN500 | 75±7 | 150±30% | 500 | 4.5 | 5.0 |

| SPMZA-4H221RN600 | 220±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4H331RM650 | 330±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H401RN650 | 400±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H501RN650 | 500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H651RN650 | 650±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H102RN650 | 1000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H152RN650 | 1500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H202RN650 | 2000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H302RN650 | 3000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4H502RN650 | 5000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M151RN500 | 105±7 | 150±30% | 500 | 4.5 | 5.0 |

| SPMZA-4M221RN600 | 220±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4M331RM650 | 330±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M401RN650 | 400±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M501RN650 | 500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M651RN650 | 650±30% | 600 | 4.5 | 5.0 | |

| SPMZA-4M102RN650 | 1000±30% | 650 | 4.5 | 5.0 | |

| SPMZA-4M152RN650 | 1500±30% | 650 | 4.5 | 5.0 | |

| SPMZA-5I151M500 | 85±7 | 150±30% | 500 | 5.5 | 5.0 |

| SPMZA-5I221M650 | 220±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I331M650 | 330±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I401M650 | 400±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I651M650 | 650±30% | 650 | 5.5 | 5.0 | |

| SPMZA-5I102M650 | 1000±30% | 650 | 5.5 | 5.0 | |

| SPMZA-6H151RN600 | 75±7 | 150±30% | 600 | 6.5 | 5.0 |

| SPMZA-6H221RN650 | 220±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H331RN650 | 330±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H401RN650 | 400±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H501RN650 | 500±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H651RN650 | 650±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H102RN650 | 1000±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6H152RN650 | 1500±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M151RN600 | 105±7 | 150±30% | 600 | 6.5 | 5.0 |

| SPMZA-6M221RN650 | 220±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M331RN650 | 330±30% | 650 | 6.5 | 5.0 | |

| SPMZA-6M401RN650 | 400±30% | 650 | 6.5 | 5.0 | |

| SPMZA-8H151RN650 | 75±7 | 150±30% | 650 | 8.0 | 5.0 |

| SPMZA-8H221RN650 | 220±30% | 650 | 8.0 | 5.0 | |

| SPMZA-8H331RN800 | 330±30% | 800 | 8.0 | 5.0 | |

| SPMZA-8H401RN900 | 400±30% | 900 | 8.0 | 5.0 | |

| SPMZA-9H151RN650 | 75±7 | 150±30% | 650 | 9.0 | 5.0 |

| SPMZA-9H221RN650 | 220±30% | 650 | 9.0 | 5.0 | |

| SPMZA-9H331RN800 | 330±30% | 800 | 9.0 | 5.0 | |

| SPMZA-9H401RN900 | 400±30% | 900 | 9.0 | 5.0 | |

Contactez-nous

En attente de votre email, nous vous répondrons dans les 12 heures avec des informations précieuses dont vous aviez besoin.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt