دسته بندی محصولات

- فیوز حرارتی 32

- فیوزهای سطح سطح 12

- درمانگر 36

- نگهدارنده فیوز Mount PCB 27

- سیم کشی 6

- دارندگان فیوز تیغه 17

- ترموستات 50

- فیوز الکتریکی 24

- سنسور دمای خودرو 7

- قطع کننده مدار حرارتی 22

- صندوقچه فیوز 36

- سنسور دما 75

- سوئیچ حرارتی 68

- فیوز ماشین 20

- پیچ و مهره 8

برچسب های محصول

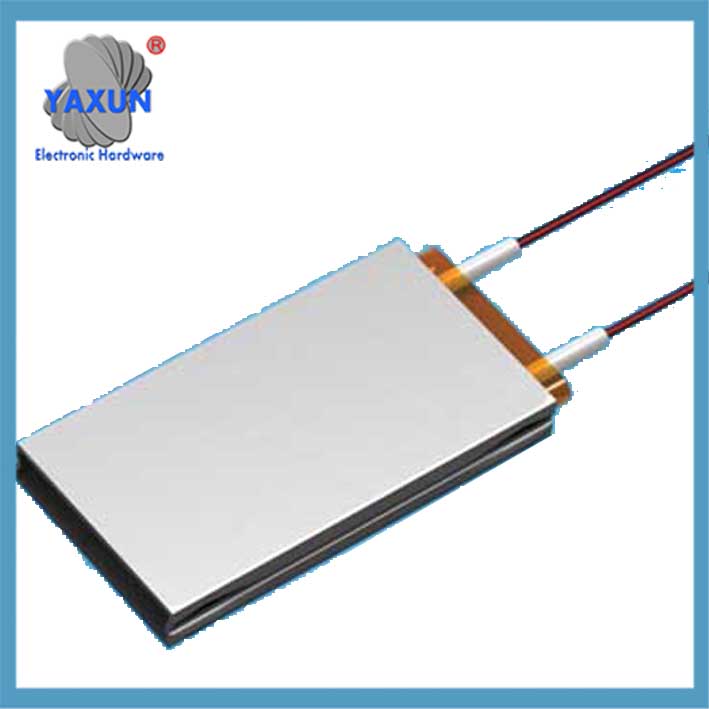

ترمیستورهای PTC برای گرمایش با دمای ثابت

بخاری های دمای ثابت PTC دستگاه های گرمایشی هستند که برای استفاده از ویژگی های گرمایش دمای ثابت ترمیستورهای PTC طراحی شده اند.. در پایین- و کاربردهای گرمایش با توان متوسط, بخاری های PTC نسبت به عناصر گرمایش سنتی مزایایی دارند, مانند گرمایش با دمای ثابت, بدون شعله باز, راندمان تبدیل حرارت بالا, حداقل تاثیر ولتاژ منبع تغذیه, و طول عمر طولانی. استفاده از آنها در وسایل گرمایش الکتریکی به طور فزاینده ای مورد علاقه R&مهندسین دی.

بررسی اجمالی محصول

The constant temperature heating characteristics of PTC thermistors for constant temperature heating are determined by the material properties. The principle is that when power is applied to the PTC thermistor, self-heating causes the component’s temperature to rise, causing the resistance value to enter the transition region and the current to drop rapidly. Consequently, the surface temperature of the PTC thermistor remains constant. این دما صرفاً به دمای کوری ترمیستور PTC و ولتاژ اعمال شده بستگی دارد., و تا حد زیادی مستقل از دمای محیط است.

بخاری های دمای ثابت PTC دستگاه های گرمایشی هستند که برای استفاده از ویژگی های گرمایش دمای ثابت ترمیستورهای PTC طراحی شده اند.. در پایین- و کاربردهای گرمایش با توان متوسط, بخاری های PTC نسبت به عناصر گرمایش سنتی مزایایی دارند, مانند گرمایش با دمای ثابت, بدون شعله باز, راندمان تبدیل حرارت بالا, حداقل تاثیر ولتاژ منبع تغذیه, و طول عمر طولانی. استفاده از آنها در وسایل گرمایش الکتریکی به طور فزاینده ای مورد علاقه R&مهندسین دی.

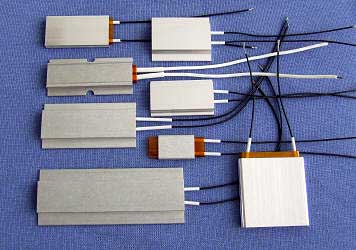

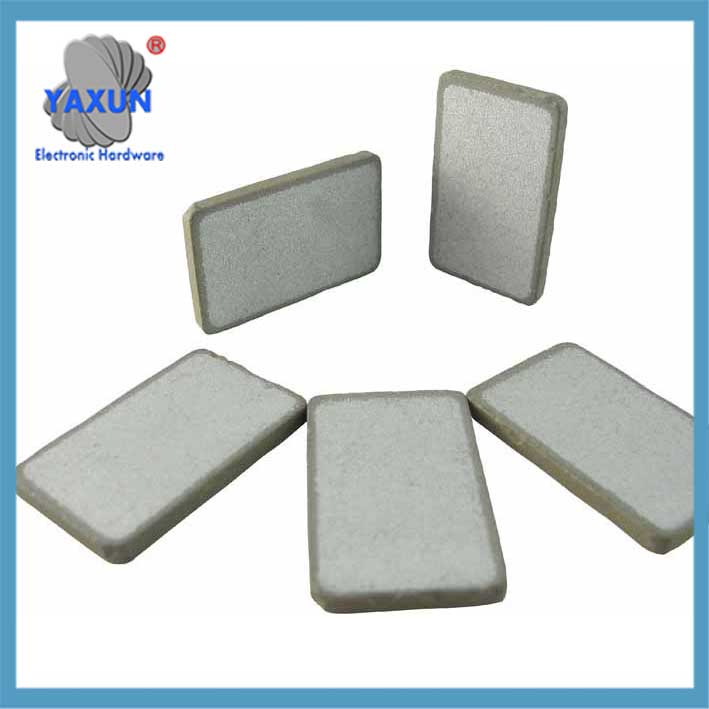

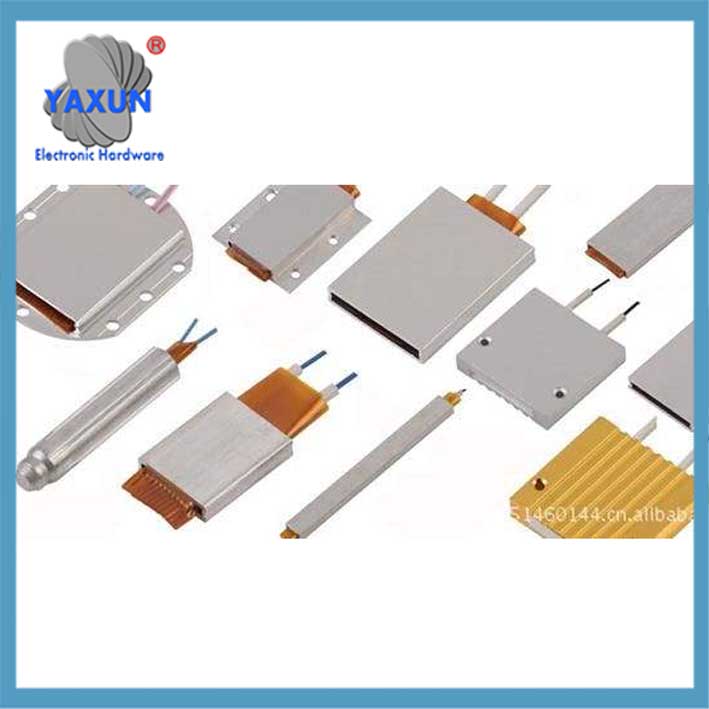

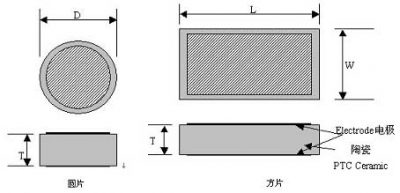

PTC thermistors for constant temperature heating can be manufactured in a variety of shapes and specifications. اشکال رایج شامل دیسک ها می باشد, مستطیل ها, نوارها, حلقه ها, and honeycomb pores. Combining the above-mentioned PTC heating elements with metal components can create various high-power PTC heaters.

طراحی اپلیکیشن

با استفاده از اصل گرمایش دمای ثابت ترمیستورهای PTC, these devices can be designed for applications such as hair straighteners, گیره مو, گیره مو, perms, perms, گیره های سرامیکی, انبر مو, اتوهای فر کننده, شانه های برقی, فر کننده مو با یون منفی, ماساژورها, مواد دافع پشه, مواد دافع پشه, دستگاه پخش کویل پشه, پخش کننده های عطر, پخش کننده های عطر, تفنگ های چسب حرارتی, heated foot baths, ماشین آلات لمینیت, فنجان قمقمه, water boilers, دستگاه های قهوه, گرم کننده های قهوه, بخاری های قهوه, فاضل آب, دستگاه پخش آب سرد و گرم, شیر گرم کن, آبگرمکن, shower heaters, دافع پشه برقی, گرمکن دست, خشک کن ها, صفحات گرم برقی, اتوهای برقی, لحیم کاری برقی, electric thermal adhesives, اتوهای فر کننده, دوش ها, fan heaters, drying rooms, بخاری برقی, بخاری برقی, air conditioning systems, air conditioning heating systems, space heaters, air heating systems, hot water kettles, Shoe dryers, shoe drying devices, گرمکن پا, صفحات گرمایش برقی, آنالایزرهای طیف, طیف درمانی, دستگاه های فیزیوتراپی, گرمایش مادون قرمز, clothes dryers, کاربراتور موتور سیکلت, مرطوب کننده های برقی, moisture-proof heating for electrical instruments, small crystal device constant temperature baths, constant temperature incubators, بطری قمقمه الکترونیکی, جعبه های عایق شده, فنجان های عایق شده, سینی های عایق شده, کابینت های عایق شده, insulated tables, صفحات گرمایش برقی, thermal therapy devices, hot coffee machines, steam beauty treatments, دستگاه های ذوب موم, ژنراتورهای بخار, مرطوب کننده ها, مرطوب کننده ها, اکسترودرهای شکلاتی, hot packs, لحیم کاری برقی, acupuncture, کاتترهای ادراری, گرمکن پا, دست خشک کن, دستگاه های آب نبات پنبه ای, ماساژورها, liquefied gas cylinder heating, بخاری های کوچک هوای گرم, سشوار, room heaters, خشک کن ها, dry cabinets, clothes dryers, industrial drying equipment, Electric dust collector hopper heater, train locomotive electric heater, mold heating, control cabinet heating moisture-proof, monitor moisture-proof, فر برقی, electric toaster, infusion box, تجهیزات پزشکی, لوازم خانگی, daily appliances, لوازم کوچک…OTC.

Model Parameters

| Ring Temperature Resistance 25℃/Ω |

دمای سطح /℃ |

حداکثر ولتاژ /حرفهای |

قطر D/mm |

طول L/mm |

عرض W/mm |

ضخامت T/mm |

| 500~1500 | 50 | 270 | 8 | 3 | ||

| 300~800 | 85 | 140 | 16 | 11 | 2.5 | |

| 150~ 400 | 90 | 140 | 16 | 11 | 2.5 | |

| 600~1500 | 100 | 270 | 20 | 2.5 | ||

| 500~1500 | 110 | 270 | 16 | 11 | 2.2 | |

| 500~1500 | 130 | 270 | 20 | 2.2 | ||

| 200~800 | 150 | 140 | 10.8 | 2.2 | ||

| 200~800 | 155 | 270 | 10.8 | 2.2 | ||

| 500~1500 | 155 | 270 | 10.8 | 2.2 | ||

| 1.5~5K | 170 | 140 | 5 | 4 | 1.6 | |

| 150~500 | 175 | 140 | 10.8 | 2.2 | ||

| 500~1500 | 180 | 270 | 10.8 | 2.2 | ||

| 200~800 | 185 | 270 | 10.8 | 2.2 | ||

| 1~3K | 195 | 270 | 8 | 2.5 | ||

| 800~2K | 230 | 270 | 19 | 12 | 2.2 | |

| 800~2K | 250 | 270 | 13 | 2.5 | ||

| 2~5K | 250 | 270 | 20 | 2.5 | ||

| 300~1K | 250 | 140 | 23.5 | 10 | 2.2 | |

| 800~2K | 255 | 270 | 23.5 | 10 | 2.2 | |

| 500~2K | 275 | 270 | 35 | 10 | 2.1 | |

| 300~800 | 280 | 140 | 24 | 15 | 2.5 | |

| 0.8~3.5K | 280 | 270 | 24 | 15 | 2.5 |

Usage Notes

1) بخاری PTC دارای کنترل خودکار دمای ثابت است, از بین بردن نیاز به سیستم کنترل دما. این جزء اصلی تمام بخاری های PTC است.

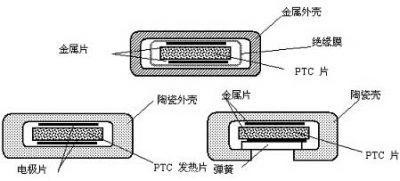

2) چهار نوع الکترود موجود است: نیکل الکترولس + نقره ای, آلومینیوم ذوب شده, آلومینیوم چاپ شده + نقره ای, و آلومینیوم چاپ شده است.

3) The operating voltage range is very wide. Even with a 2x increase in operating voltage, the surface temperature changes minimally.

4) هنگامی که چندین بخاری PTC با هم استفاده می شود, آنها باید به صورت موازی متصل شوند, در سریال نیست.

5) این محصول فاقد سیم سربی و عایق می باشد. اگر این امکان پذیر نیست, please select a model with an external insulation film or a metal housing.

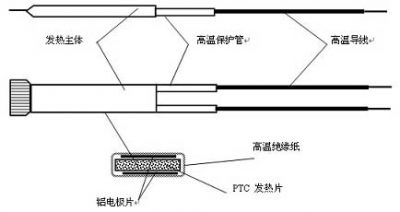

Model Parameters

| Length/mm | Width/mm | Thickness/mm | Surface Temperature/℃ | Insulation Withstand Voltage/V | Operating Voltage/V |

| 30~120 | 20 | 5.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 30 | 6.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 33 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 35 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 40 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 43 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 46 | 7.0 | 60~280 | 3750 | 100~240 |

| 30~120 | 56 | 7.0 | 60~280 | 3750 | 100~240 |

Temperatures can be designed between 60°C and 280°C, and operating voltages can be designed between 12V and 240V, بسته به نیاز مشتری.

اقدامات احتیاطی استفاده

1) After power is applied, the heating power decreases gradually and then stabilizes. قدرت پایدار بستگی به شرایط عملیاتی دارد. The power of the same PTC heater can vary several times depending on operating conditions. هر چه سریعتر اتلاف گرما انجام شود, قدرت پایدار بیشتر است; هر چه دمای سطح PTC بالاتر باشد, قدرت بالاتر.

2) دمای سطح بخاری PTC توسط خود PTC کنترل می شود و با قطع مدار قابل کنترل است., but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) هنگام استفاده از چندین PTC, آنها باید به صورت موازی متصل شوند, در سریال نیست.

Model Parameters

| طول (میلی متر) | عرض (میلی متر) | ضخامت (میلی متر) | دمای سطح (درجه سانتیگراد) | Insulation Withstand Voltage (حرفهای) | ولتاژ عملیاتی (حرفهای) |

| 24 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 24 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 35 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 48 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 60 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 8 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 10 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 13 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

| 70 above | 15 | 3.0~3.5 | 85~280 | 3750 | 100~240 |

Temperatures can be designed between 50°C and 280°C, and operating voltages can be designed between 3V and 240V, بسته به نیاز مشتری.

اقدامات احتیاطی استفاده

1) After power is applied, the heating power decreases gradually and then stabilizes. قدرت پایدار بستگی به شرایط عملیاتی دارد. The power of the same PTC heater can vary several times depending on operating conditions. هر چه سریعتر اتلاف گرما انجام شود, قدرت پایدار بیشتر است; هر چه دمای سطح PTC بالاتر باشد, قدرت بالاتر.

2) دمای سطح بخاری PTC توسط خود PTC کنترل می شود و با قطع مدار قابل کنترل است., but not by adjusting the voltage.

3) While PTCs are inherently highly reliable and have a long lifespan, improper assembly can result in unstable power and temperature.

4) هنگام استفاده از چندین PTC, آنها باید به صورت موازی متصل شوند, در سریال نیست.

با ما تماس بگیرید

منتظر ایمیل خود هستید, ما به شما پاسخ خواهیم داد 12 ساعت با اطلاعات ارزشمند مورد نیاز شما.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt