продуктови категории

- термичен предпазител 32

- предпазители за повърхностен монтаж 12

- термистор 36

- Държач за предпазител за монтаж на печатна платка 27

- Окабеляване 6

- Държачи за ножови предпазители 17

- термостат 50

- Електрически предпазител 24

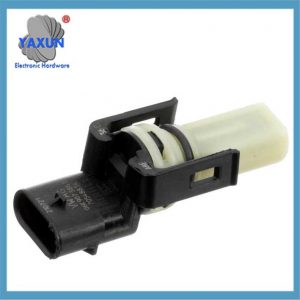

- Автомобилен сензор за температура 7

- Термичен прекъсвач 22

- Държач на кутия с предпазители 36

- Температурен сензор 75

- Термоключ 68

- Автомобилен предпазител 20

- Предпазители с болтове 8

Продуктови етикети

Функции и класификация на автомобилни температурни сензори

Автомобилният температурен сензор е основният компонент на системата за термично управление на автомобила ( Сензор за температура на охлаждащата течност, Сензор за температура на входящия въздух, Сензор за температура на трансмисионното масло, Сензор за външна/вътрешна температура), който предоставя ключови данни за блока за управление на двигателя (ECU) за оптимизиране на работата на автомобила чрез наблюдение на температурните промени в различни зони. Основните класификации и функции са както следва:

Температурните сензори се използват широко в автомобилите, като сензори за температура на охлаждащата течност (сензори за температура на водата), сензори за входяща температура, сензори за температура на трансмисионното масло, и т.н. Основната функция на тези сензори е да следят температурата на различни части и да връщат данните към ECU за регулиране на работните параметри на двигателя и системите на автомобила.

Следващото нещо, което трябва да вземете предвид, е типът и принципът на работа на сензора. Често използвани са термистори с отрицателен температурен коефициент (NTC), термодвойки, платинени съпротивителни детектори (RTD), и т.н. Сред тях, NTC е най-широко използваният. например, сензорът за температура на водата използва характеристиката, че съпротивлението на NTC намалява с повишаване на температурата. Базирани на силиций сензори като KTY84 се използват в случаи с по-висока точност, като откриване на температурата на маслото. Обхватът на измерване и точността на различните сензори имат свои собствени характеристики. например, термодвойките са подходящи за среда с висока температура, но точността е ниска; платинените съпротивителни детектори имат висока точност, но висока цена.

Мястото на инсталиране също е критично. например, сензорът за температура на водата обикновено е близо до водната риза на блока на двигателя или главата на цилиндъра, докато сензорът за входяща температура е във всмукателната тръба или разходомера за въздух. Местоположението на сензора за външна температура варира, някои са в предната броня, някои са близо до резервоара за вода, и разликата между различните модели е голяма. Изборът на тези места пряко влияе върху точността на измерването и издръжливостта на сензора.

По отношение на функцията, температурният сензор има голямо влияние върху работата на автомобила. Сензорите за необичайна температура на водата могат да причинят проблеми като трудно стартиране на студено, нестабилна скорост на празен ход, и увеличен разход на гориво. Повреда на сензора за входяща температура може да причини дисбаланс в съотношението на сместа и да повлияе на мощността. Тези случаи на повреда илюстрират значението на сензорите, особено въздействието на неточността на данните върху вземането на решения за ECU.

Разделът за справяне с грешки трябва да обобщи общи проблеми и решения. например, отклонение на сигнала, стареене на линията, физическо увреждане, и т.н. По време на диагностика, действителната температура може да се сравни чрез измерване на съпротивлението, напрежение или поток от данни. Тук трябва да подчертаем важността на редовната поддръжка и правилната инсталация, за да избегнем големи повреди, причинени от незначителни проблеми.

Накрая, развитието на нови технологии също подобрява работата на сензорите. например, eRTS сензорът на Continental може директно да измерва температурата на ротора на двигателя с точност от ±3°C, намаляване на използването на редкоземни материали. Тази иновация демонстрира напредъка на температурните сензори в областта на електрическите превозни средства.

🔧 Аз. Основни типове и технически принципи

Сензор за температура на охлаждащата течност

Местоположение: Цилиндров блок на двигателя/водна риза на цилиндровата глава (мейнстрийм позиция за 65% на модели), близо до термостата или шунтиращата тръба на охлаждащата течност.

Принцип: Използване на термистор с отрицателен температурен коефициент (NTC), съпротивлението пада до 0,3 kΩ при 80 ℃ (2.5kΩ при 20 ℃).

Функция: Правилно количество за инжектиране при ниска температура (+30% компенсация при студен старт), регулирайте ъгъла на изпреварване на запалването (-20℃ предварително 8–12°), контрол на празен ход (ниската температура се повишава до 1200–1500 об./мин).

Сензор за температура на входящия въздух

Местоположение: Всмукателна тръба или вътрешен дебитомер 5.

Въздействие: Ненормален сигнал води до дисбаланс на сместа, причинявайки затруднения при студен старт или слабо ускорение.

Сензор за температура на трансмисионното масло

Местоположение: Вътре в масления съд на пластината на клапана на автоматичната скоростна кутия 5.

Функция: Осигурете температурна основа за логиката на смяната, контрол на налягането на маслото и блокиращ съединител.

Сензор за външна/вътрешна температура

Екстериор: Зад предната броня или предната стена на кабината, контролиране на температурната зона на автоматичния климатик.

Интериор: Вентилационният канал под арматурното табло следи температурата на околната среда в купето.

⚙️ II. Технологична еволюция и иновации

| Тип сензор | Място на монтаж | функция | Изисквания за точност |

| Сензор за температура на охлаждащата течност | Периферия на водна риза/термостат на цилиндровата глава | Правилно количество впръскано гориво (ниска температура +30% обезщетение), регулирайте ъгъла на запалване (8-12° предварително при -20°C) | ±3°C (2025 нов модел) |

| Сензор за входяща температура | Всмукателна тръба или разходомер на въздуха | Правилно съотношение въздух-гориво, повредата ще причини трудности при стартиране при горещ режим и прекомерни емисии | ±5 ℃ |

| Сензор за температура на трансмисионното масло | Вътрешна маслена плоча на клапана | Контролирайте логиката на превключване и налягането на маслото, за да предотвратите повреда в смазването, причинена от висока температура | ±2 ℃ |

| Сензор за температура на изгорелите газове | Зад трипътен катализатор | Следете прегряването на катализатора (300-400°C работно състояние) и задействащ защитен механизъм | ±15 ℃ |

| Сензор за температура на ротора на двигателя | Вътрешен ротор на синхронен двигател с постоянен магнит | Директно следете температурата на магнита, за да предотвратите високотемпературно демагнетизиране при 150°C и да намалите употребата на редкоземни метали | ±3°C (eRTS технология) |

| Сензор за температура на батерията | Термична зона за управление на батерията | Уверете се, че литиевата батерия е в диапазона на работната температура (-20℃~60℃) за предотвратяване на топлинно бягство | ±1 ℃ |

Пробив в прецизното измерване: Новият eRTS сензор директно измерва температурата на ротора на двигателя чрез пиезоелектрична ултразвукова технология, с повишена точност от ±15℃ до ±3℃, намаляване на зависимостта от редкоземни материали.

Надграждане на материала: Базираният на силиций сензор KTY84 може да работи при -40℃~300℃, и неговите линейни характеристики съпротивление-температура са подходящи за високотемпературни сценарии като дизелови системи за впръскване.

⚠️ III. Типични повреди и диагностика

IV. Разлики в позицията на монтаж и въздействията

Същата функция, различна позиция: Сензорът за външна температура се намира в дренажния жлеб или предната броня на модела Sagitar, докато някои модели са интегрирани под огледалото за обратно виждане.

Корелация на точността: Когато сензорът за охлаждащата течност е в пряк контакт с течността, грешката е ≤±15℃, и косвеното изчисление (като например статорът на двигателя, който определя ротора) има грешка до 15 ℃.

💎 Резюме

Температурният сензор е като “нервни окончания” на колата, и неговата точност пряко влияе върху ефективността на изходната мощност и консумацията на енергия. С развитието на електрическите превозни средства, високопрецизна технология за директно измерване (като eRTS) постепенно заменя режима на косвен извод, насърчаване на усъвършенстваната революция на системата за управление на топлината. Редовното откриване на характеристиките на съпротивлението и стабилността на сигнала е ключът към предотвратяването на системни повреди.

Свържете се с нас

Чакам вашия имейл, ние ще ви отговорим в рамките на 12 часа с ценна информация, от която се нуждаете.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt