Категории продуктов

- термопредохранитель 32

- предохранители для поверхностного монтажа 12

- термистор 36

- Держатель предохранителя для монтажа на печатной плате 27

- Жгут проводов 6

- Держатели лопастных предохранителей 17

- термостат 50

- Электрический предохранитель 24

- Датчик автомобильной температуры 7

- Тепловой выключатель 22

- Держатель блока предохранителей 36

- Датчик температуры 75

- Термовыключатель 68

- Автомобильный предохранитель 20

- Закрепить предохранители 8

Теги продукта

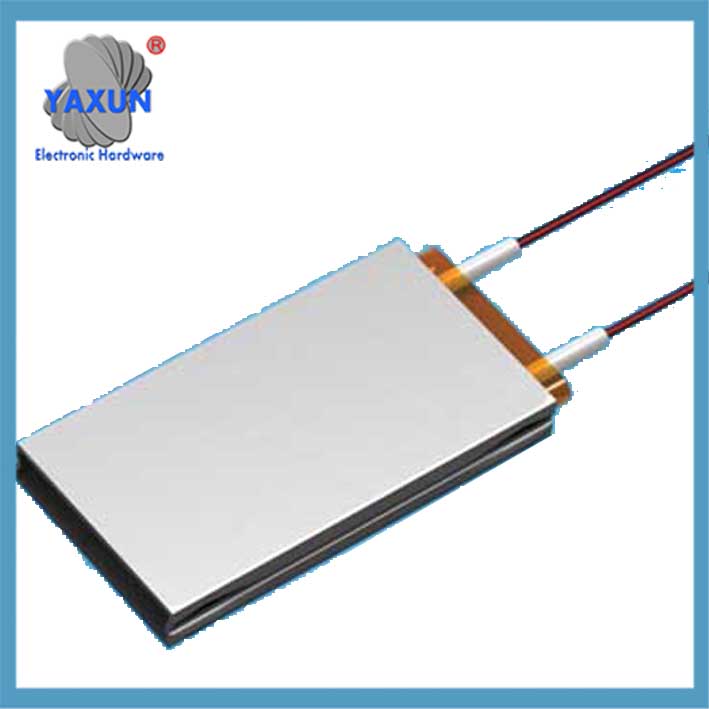

Термисторы PTC для нагрева при постоянной температуре

Нагреватели с постоянной температурой PTC — это нагревательные устройства, предназначенные для использования характеристик нагрева при постоянной температуре термисторов с PTC.. В низком- и системы отопления средней мощности, Нагреватели PTC имеют преимущества перед традиционными нагревательными элементами., такие как постоянное нагревание температуры, никакого открытого огня, высокая эффективность преобразования тепла, минимальное влияние напряжения питания, и долгий срок службы. Их использование в электронагревательных приборах все чаще отдается предпочтение Р.&D Инженеры.

Обзор продукта

Характеристики нагрева при постоянной температуре термисторов PTC для нагрева при постоянной температуре определяются свойствами материала.. Принцип заключается в том, что при подаче питания на термистор PTC, самонагревание приводит к повышению температуры компонента., вызывая попадание значения сопротивления в переходную область и ток быстро падает. Следовательно, температура поверхности термистора PTC остается постоянной. Эта температура зависит исключительно от температуры Кюри термистора PTC и приложенного напряжения., и практически не зависит от температуры окружающей среды.

Нагреватели с постоянной температурой PTC — это нагревательные устройства, предназначенные для использования характеристик нагрева при постоянной температуре термисторов с PTC.. В низком- и системы отопления средней мощности, Нагреватели PTC имеют преимущества перед традиционными нагревательными элементами., такие как постоянное нагревание температуры, никакого открытого огня, высокая эффективность преобразования тепла, минимальное влияние напряжения питания, и долгий срок службы. Их использование в электронагревательных приборах все чаще отдается предпочтение Р.&D Инженеры.

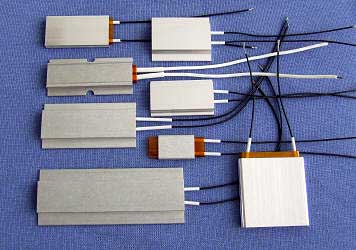

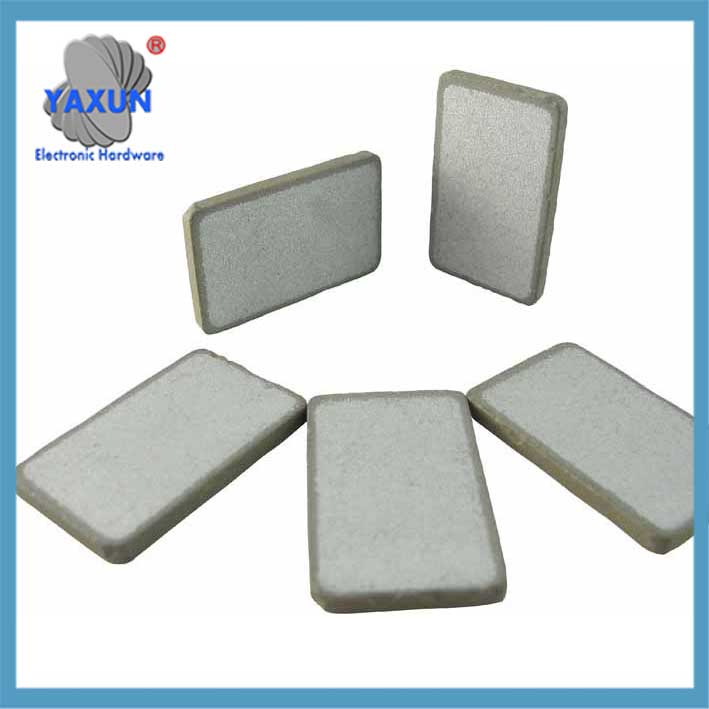

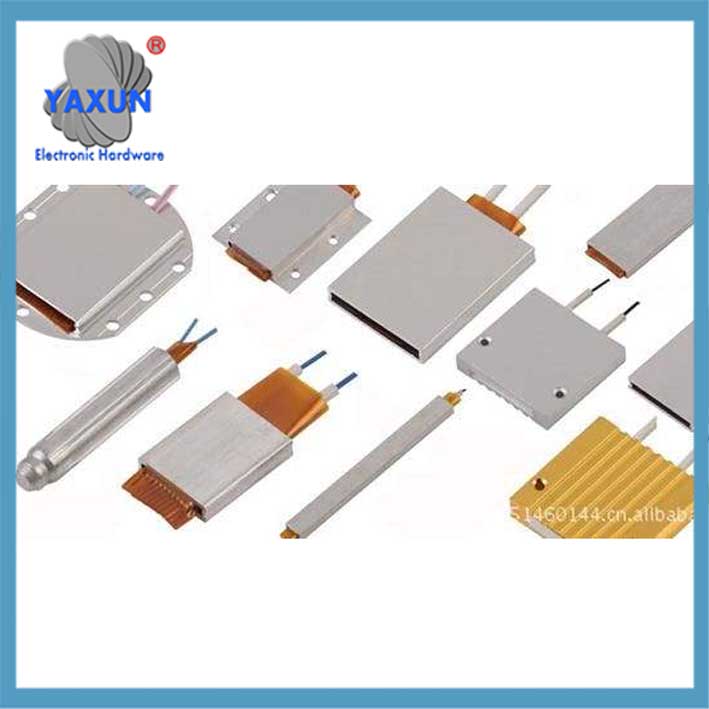

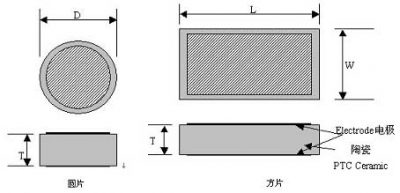

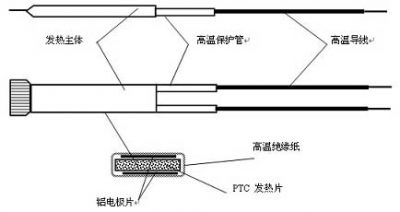

PTC-термисторы для нагрева при постоянной температуре могут изготавливаться в различных формах и характеристиках.. Общие формы включают диски., прямоугольники, полоски, кольца, и сотовые поры. Комбинируя вышеупомянутые нагревательные элементы PTC с металлическими компонентами, можно создавать различные мощные нагреватели PTC..

Дизайн приложений

Использование принципа нагрева постоянной температуры термисторов PTC., эти устройства могут быть предназначены для таких применений, как выпрямители для волос., заколки для волос, заколки для волос, химическая завивка, химическая завивка, керамическая завивка, щипцы для волос, щипцы для завивки, электрические расчески, бигуди с отрицательными ионами, Массагеры, репелленты от комаров, репелленты от комаров, диспенсеры для спиралей от комаров, дозаторы ароматов, дозаторы духов, пистолеты для горячего клея-расплава, ванночки для ног с подогревом, ламинирующие машины, термос чашки, водогрейные котлы, Кофейные машины, подогреватели кофе, нагреватели для кофе, диспенсеры для воды, диспенсеры для горячей и холодной воды, подогреватели молока, водонагреватели, обогреватели для душа, электрические отпугиватели комаров, грелки для рук, сушилки, электрические плиты, электрические утюги, Электрические пайки, электрические термоклеи, щипцы для завивки, душ, тепловентиляторы, сушильные камеры, электрические обогреватели, электрические обогреватели, системы кондиционирования воздуха, системы отопления кондиционирования воздуха, обогреватели, системы воздушного отопления, чайники с горячей водой, Обувные сушилки, устройства для сушки обуви, стопы, Электрические нагревательные пластины, Анализаторы спектра, спектр терапии, Устройства физиотерапии, инфракрасное отопление, сушилки для одежды, мотоциклевые карбюраторы, Электрические увлажнители, Влагостойкий нагрев для электрических инструментов, Маленькое кристаллическое устройство для ванн с постоянной температурой, Постоянные температурные инкубаторы, Электронные термос бутылки, изолированные коробки, изолированные чашки, изолированные лотки, изолированные шкафы, изолированные столы, Электрические нагревательные пластины, Устройства терапии, Горячие кофейни, Паровые красоты, Восковые платы, парогенераторы, увлажнители, увлажнители, шоколадные экструдеры, горячие пакеты, Электрические пайки, иглоукалывание, мочевые катетеры, стопы, ручные сушилки, хлопковые машины, Массагеры, отопление баллона сжиженным газом, Маленькие теплые нагреватели, фены, нагреватели комнаты, сушилки, сухие шкафы, сушилки для одежды, Промышленное сушильное оборудование, Электрический нагреватель бункера пылесборника, электрообогреватель локомотива поезда, нагревание плесени, Управление шкафом нагревании влаги, Мониторинг влаги, электрическая духовка, Электрический тостер, инфузионная коробка, медицинское оборудование, бытовая техника, Ежедневные приборы, небольшие приборы…и т. д..

Параметры модели

| Температурная устойчивость кольца 25℃/ч |

Температура поверхности /℃ |

Максимальное напряжение /В |

Диаметр Д/мм |

Длина L/мм |

Ширина С мм |

Толщина Т/мм |

| 500~ 1500 | 50 | 270 | 8 | 3 | ||

| 300~ 800 | 85 | 140 | 16 | 11 | 2.5 | |

| 150~ 400 | 90 | 140 | 16 | 11 | 2.5 | |

| 600~ 1500 | 100 | 270 | 20 | 2.5 | ||

| 500~ 1500 | 110 | 270 | 16 | 11 | 2.2 | |

| 500~ 1500 | 130 | 270 | 20 | 2.2 | ||

| 200~ 800 | 150 | 140 | 10.8 | 2.2 | ||

| 200~ 800 | 155 | 270 | 10.8 | 2.2 | ||

| 500~ 1500 | 155 | 270 | 10.8 | 2.2 | ||

| 1.5~ 5K | 170 | 140 | 5 | 4 | 1.6 | |

| 150~ 500 | 175 | 140 | 10.8 | 2.2 | ||

| 500~ 1500 | 180 | 270 | 10.8 | 2.2 | ||

| 200~ 800 | 185 | 270 | 10.8 | 2.2 | ||

| 1~ 3K | 195 | 270 | 8 | 2.5 | ||

| 800~ 2K | 230 | 270 | 19 | 12 | 2.2 | |

| 800~ 2K | 250 | 270 | 13 | 2.5 | ||

| 2~ 5K | 250 | 270 | 20 | 2.5 | ||

| 300~ 1K | 250 | 140 | 23.5 | 10 | 2.2 | |

| 800~ 2K | 255 | 270 | 23.5 | 10 | 2.2 | |

| 500~ 2K | 275 | 270 | 35 | 10 | 2.1 | |

| 300~ 800 | 280 | 140 | 24 | 15 | 2.5 | |

| 0.8~ 3,5k | 280 | 270 | 24 | 15 | 2.5 |

Заметки об использовании

1) Нагреватель PTC имеет автоматический контроль постоянной температуры., устранение необходимости в системе контроля температуры. Это основной компонент всех PTC-нагревателей..

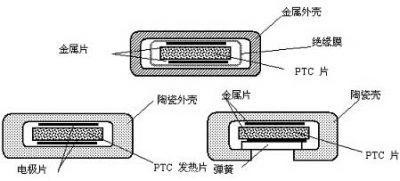

2) Доступны четыре типа электродов.: химический никель + серебро, выдутый из расплава алюминий, печатный алюминий + серебро, и печатный алюминий.

3) Диапазон рабочего напряжения очень широк.. Даже при увеличении рабочего напряжения в 2 раза, температура поверхности меняется минимально.

4) При совместном использовании нескольких нагревателей PTC, они должны быть связаны параллельно, не в серии.

5) Этот продукт не имеет подводящих проводов или изоляции.. Если это неосуществимо, пожалуйста, выберите модель с внешней изоляционной пленкой или металлическим корпусом.

Параметры модели

| Длина/мм | Ширина/мм | Толщина/мм | Температура поверхности/℃ | Выдерживаемое напряжение изоляции/В | Рабочее напряжение/В |

| 30~ 120 | 20 | 5.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 30 | 6.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 33 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 35 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 40 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 43 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 46 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 56 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

Температуру можно регулировать от 60°C до 280°C., и рабочее напряжение может быть рассчитано от 12 В до 240 В., в зависимости от требований заказчика.

Меры предосторожности при использовании

1) После подачи питания, мощность нагрева постепенно снижается, а затем стабилизируется. Стабильная мощность зависит от условий эксплуатации. Мощность одного и того же ПТК-нагревателя может меняться в несколько раз в зависимости от условий эксплуатации.. Чем быстрее рассеяние тепла, Чем больше стабильная сила; тем выше температура поверхности PTC, Чем выше сила.

2) Температура поверхности нагревателя PTC контролируется самим PTC и может контролироваться путем отключения цепи., но не путем регулировки напряжения.

3) Хотя PTC по своей сути очень надежны и имеют длительный срок службы., неправильная сборка может привести к нестабильной мощности и температуре.

4) При использовании нескольких PTC, они должны быть связаны параллельно, не в серии.

Параметры модели

| Длина (мм) | Ширина (мм) | Толщина (мм) | Температура поверхности (°С) | Выдерживаемое напряжение изоляции (В) | Рабочее напряжение (В) |

| 24 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 24 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 выше | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

Температуру можно регулировать от 50°C до 280°C., и рабочее напряжение может быть рассчитано от 3 В до 240 В., в зависимости от требований заказчика.

Меры предосторожности при использовании

1) После подачи питания, мощность нагрева постепенно снижается, а затем стабилизируется. Стабильная мощность зависит от условий эксплуатации. Мощность одного и того же ПТК-нагревателя может меняться в несколько раз в зависимости от условий эксплуатации.. Чем быстрее рассеяние тепла, Чем больше стабильная сила; тем выше температура поверхности PTC, Чем выше сила.

2) Температура поверхности нагревателя PTC контролируется самим PTC и может контролироваться путем отключения цепи., но не путем регулировки напряжения.

3) Хотя PTC по своей сути очень надежны и имеют длительный срок службы., неправильная сборка может привести к нестабильной мощности и температуре.

4) При использовании нескольких PTC, они должны быть связаны параллельно, не в серии.

Связаться с нами

Жду вашего письма, мы ответим вам в течение 12 часы с ценной информацией, которая вам нужна.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt