Categorias de Produtos

- fusível térmico 32

- fusíveis de montagem em superfície 12

- termistor 36

- Suporte de fusível para montagem em PCB 27

- Chicote de fiação 6

- Porta-fusíveis de lâmina 17

- termostato 50

- Fusível elétrico 24

- Sensor de temperatura automotiva 7

- Disjuntor térmico 22

- Porta-caixa de fusíveis 36

- Sensor de temperatura 75

- Interruptor térmico 68

- Fusível do carro 20

- Fusíveis aparafusados 8

Etiquetas de produto

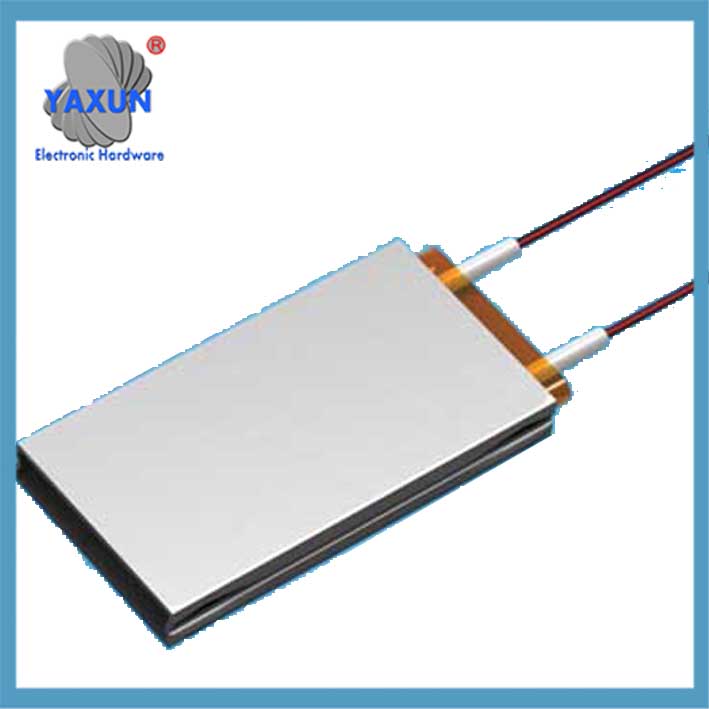

Termistores PTC para aquecimento em temperatura constante

Os aquecedores de temperatura constante PTC são dispositivos de aquecimento projetados para utilizar as características de aquecimento de temperatura constante dos termistores PTC.. Em baixo- e aplicações de aquecimento de média potência, Os aquecedores PTC oferecem vantagens em relação aos elementos de aquecimento tradicionais, como aquecimento constante de temperatura, sem chamas abertas, alta eficiência de conversão de calor, influência mínima da tensão da fonte de alimentação, e uma longa vida útil. A sua utilização em aparelhos de aquecimento eléctrico é cada vez mais favorecida pela R&D Engenheiros.

Visão geral do produto

As características de aquecimento a temperatura constante dos termistores PTC para aquecimento a temperatura constante são determinadas pelas propriedades do material. O princípio é que quando a energia é aplicada ao termistor PTC, o autoaquecimento faz com que a temperatura do componente aumente, fazendo com que o valor da resistência entre na região de transição e a corrente caia rapidamente. Consequentemente, a temperatura da superfície do termistor PTC permanece constante. Esta temperatura depende unicamente da temperatura Curie do termistor PTC e da tensão aplicada, e é amplamente independente da temperatura ambiente.

Os aquecedores de temperatura constante PTC são dispositivos de aquecimento projetados para utilizar as características de aquecimento de temperatura constante dos termistores PTC.. Em baixo- e aplicações de aquecimento de média potência, Os aquecedores PTC oferecem vantagens em relação aos elementos de aquecimento tradicionais, como aquecimento constante de temperatura, sem chamas abertas, alta eficiência de conversão de calor, influência mínima da tensão da fonte de alimentação, e uma longa vida útil. A sua utilização em aparelhos de aquecimento eléctrico é cada vez mais favorecida pela R&D Engenheiros.

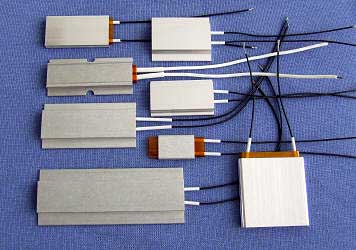

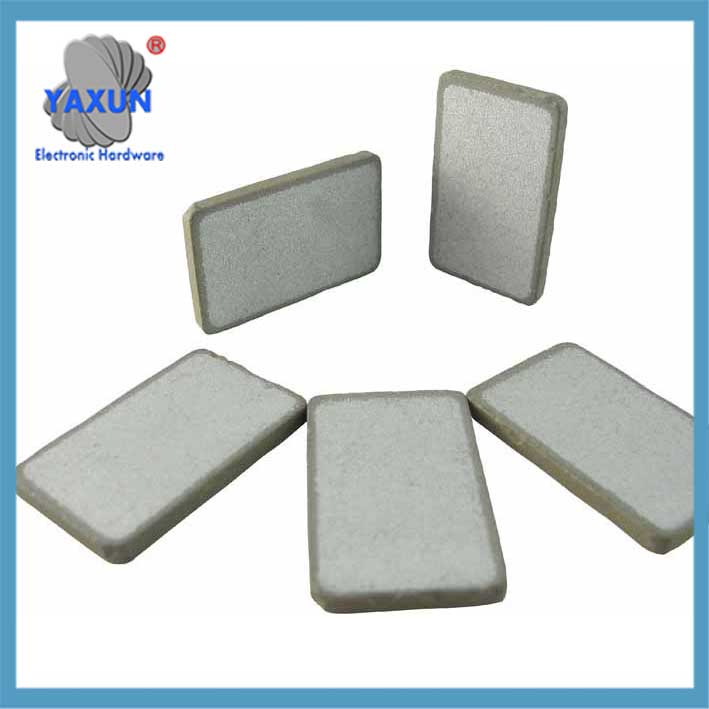

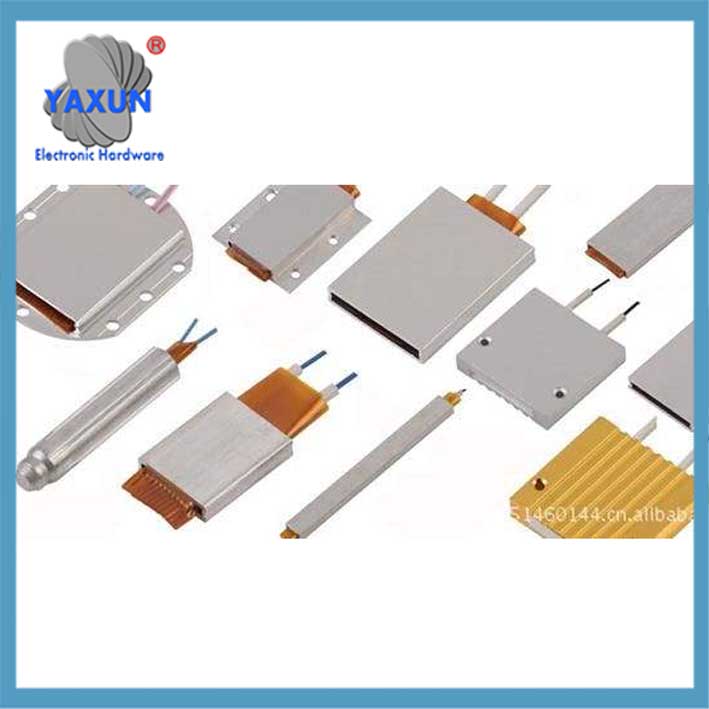

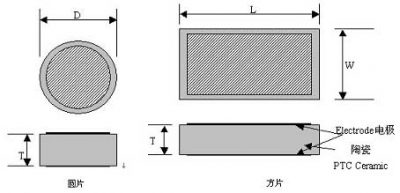

Os termistores PTC para aquecimento a temperatura constante podem ser fabricados em uma variedade de formatos e especificações. Formas comuns incluem discos, retângulos, tiras, anéis, e poros de favo de mel. A combinação dos elementos de aquecimento PTC mencionados acima com componentes metálicos pode criar vários aquecedores PTC de alta potência.

Design de aplicativos

Utilizando o princípio de aquecimento de temperatura constante dos termistores PTC, esses dispositivos podem ser projetados para aplicações como alisadores de cabelo, grampos de cabelo, grampos de cabelo, autorizações, autorizações, permanentes de cerâmica, pinça de cabelo, ferros de ondulação, pentes elétricos, rolos de cabelo de íon negativo, Massagers, repelentes de mosquitos, repelentes de mosquitos, dispensadores de bobina de mosquito, dispensadores de fragrâncias, dispensadores de perfume, pistolas de cola quente, pedilúvios aquecidos, máquinas de laminação, copos térmicos, caldeiras de água, máquinas de café, aquecedores de café, aquecedores de café, dispensadores de água, dispensadores de água quente e fria, aquecedores de leite, aquecedores de água, aquecedores de chuveiro, repelentes elétricos de mosquitos, aquecedores de mãos, secadores, placas elétricas, ferros elétricos, Ferros de solda elétrica, adesivos térmicos elétricos, ferros de ondulação, chuveiros, aquecedores de ventilador, salas de secagem, Aquecedores elétricos, Aquecedores elétricos, sistemas de ar condicionado, sistemas de aquecimento de ar condicionado, aquecedores de ambiente, sistemas de aquecimento de ar, chaleiras de água quente, Secadores de sapatos, dispositivos de secagem de sapatos, Aquecedores de pé, Placas de aquecimento elétrico, Analisadores de espectro, Terapia de espectro, Dispositivos de fisioterapia, aquecimento infravermelho, secadores de roupa, Carburadores de motocicleta, umidificadores elétricos, Aquecimento à prova de umidade para instrumentos elétricos, banhos de temperatura constante com pequenos dispositivos de cristal, incubadoras de temperatura constantes, garrafas térmicas eletrônicas, caixas isoladas, copos isolados, bandejas isoladas, armários isolados, mesas isoladas, Placas de aquecimento elétrico, Dispositivos de terapia térmica, Máquinas de café quente, Tratamentos de beleza a vapor, Melter de cera, geradores de vapor, umidificadores, umidificadores, Extrusores de chocolate, bolsas quentes, Ferros de solda elétrica, acupuntura, cateteres urinários, Aquecedores de pé, secadores de mão, Máquinas de algodão doce, Massagers, aquecimento de cilindro de gás liquefeito, Pequenos aquecedores de ar quente, secadores de cabelo, Aquecedores da sala, secadores, armários secos, secadores de roupa, Equipamento de secagem industrial, Aquecedor elétrico da tremonha do coletor de pó, aquecedor elétrico de locomotiva de trem, aquecimento do molde, Aquecimento de controle à prova de umidade do gabinete, Monitore à prova de umidade, forno elétrico, Torradeira elétrica, caixa de infusão, Equipamento médico, Aparelhos domésticos, aparelhos diários, pequenos aparelhos…etc..

Parâmetros do modelo

| Resistência à temperatura do anel 25℃/h |

Temperatura da superfície /℃ |

Tensão Máxima /V |

Diâmetro D/mm |

Comprimento L/mm |

Largura Com mm |

Grossura T/mm |

| 500~ 1500 | 50 | 270 | 8 | 3 | ||

| 300~ 800 | 85 | 140 | 16 | 11 | 2.5 | |

| 150~ 400 | 90 | 140 | 16 | 11 | 2.5 | |

| 600~ 1500 | 100 | 270 | 20 | 2.5 | ||

| 500~ 1500 | 110 | 270 | 16 | 11 | 2.2 | |

| 500~ 1500 | 130 | 270 | 20 | 2.2 | ||

| 200~ 800 | 150 | 140 | 10.8 | 2.2 | ||

| 200~ 800 | 155 | 270 | 10.8 | 2.2 | ||

| 500~ 1500 | 155 | 270 | 10.8 | 2.2 | ||

| 1.5~ 5k | 170 | 140 | 5 | 4 | 1.6 | |

| 150~ 500 | 175 | 140 | 10.8 | 2.2 | ||

| 500~ 1500 | 180 | 270 | 10.8 | 2.2 | ||

| 200~ 800 | 185 | 270 | 10.8 | 2.2 | ||

| 1~ 3k | 195 | 270 | 8 | 2.5 | ||

| 800~ 2k | 230 | 270 | 19 | 12 | 2.2 | |

| 800~ 2k | 250 | 270 | 13 | 2.5 | ||

| 2~ 5k | 250 | 270 | 20 | 2.5 | ||

| 300~ 1k | 250 | 140 | 23.5 | 10 | 2.2 | |

| 800~ 2k | 255 | 270 | 23.5 | 10 | 2.2 | |

| 500~ 2k | 275 | 270 | 35 | 10 | 2.1 | |

| 300~ 800 | 280 | 140 | 24 | 15 | 2.5 | |

| 0.8~ 3,5k | 280 | 270 | 24 | 15 | 2.5 |

Notas de uso

1) O aquecedor PTC possui controle automático de temperatura constante, eliminando a necessidade de um sistema de controle de temperatura. É o componente principal de todos os aquecedores PTC.

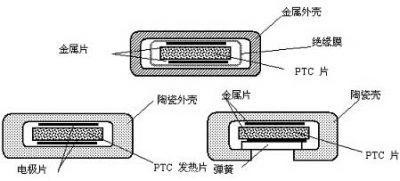

2) Quatro tipos de eletrodos estão disponíveis: níquel sem eletrólito + prata, alumínio fundido, alumínio impresso + prata, e alumínio impresso.

3) A faixa de tensão operacional é muito ampla. Mesmo com um aumento de 2x na tensão operacional, a temperatura da superfície muda minimamente.

4) Quando vários aquecedores PTC são usados juntos, Eles devem estar conectados em paralelo, não em série.

5) Este produto não possui fios condutores ou isolamento. Se isso não for viável, selecione um modelo com filme de isolamento externo ou caixa de metal.

Parâmetros do modelo

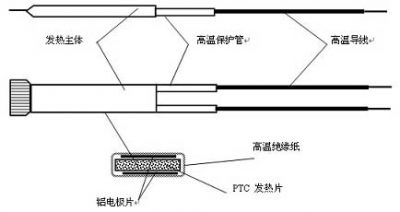

| Comprimento/mm | Largura/mm | Espessura/mm | Temperatura da superfície/℃ | Tensão suportável de isolamento/V | Tensão operacional/V |

| 30~ 120 | 20 | 5.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 30 | 6.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 33 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 35 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 40 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 43 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 46 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

| 30~ 120 | 56 | 7.0 | 60~ 280 | 3750 | 100~ 240 |

As temperaturas podem ser projetadas entre 60°C e 280°C, e tensões operacionais podem ser projetadas entre 12V e 240V, dependendo dos requisitos do cliente.

Precauções de uso

1) Depois que a energia é aplicada, a potência de aquecimento diminui gradualmente e depois estabiliza. A potência estável depende das condições de operação. A potência do mesmo aquecedor PTC pode variar várias vezes dependendo das condições de operação. Quanto mais rápido a dissipação de calor, quanto maior o poder estável; quanto maior a temperatura da superfície do PTC, Quanto maior o poder.

2) A temperatura da superfície do aquecedor PTC é controlada pelo próprio PTC e pode ser controlada desconectando o circuito, mas não ajustando a tensão.

3) Embora os PTCs sejam inerentemente altamente confiáveis e tenham uma longa vida útil, montagem inadequada pode resultar em energia e temperatura instáveis.

4) Ao usar vários PTCs, Eles devem estar conectados em paralelo, não em série.

Parâmetros do modelo

| Comprimento (milímetros) | Largura (milímetros) | Grossura (milímetros) | Temperatura da superfície (°C) | Tensão suportável de isolamento (V) | Tensão operacional (V) |

| 24 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 24 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 35 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 48 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 60 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 8 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 10 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 13 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

| 70 acima | 15 | 3.0~ 3.5 | 85~ 280 | 3750 | 100~ 240 |

As temperaturas podem ser projetadas entre 50°C e 280°C, e tensões operacionais podem ser projetadas entre 3V e 240V, dependendo dos requisitos do cliente.

Precauções de uso

1) Depois que a energia é aplicada, a potência de aquecimento diminui gradualmente e depois estabiliza. A potência estável depende das condições de operação. A potência do mesmo aquecedor PTC pode variar várias vezes dependendo das condições de operação. Quanto mais rápido a dissipação de calor, quanto maior o poder estável; quanto maior a temperatura da superfície do PTC, Quanto maior o poder.

2) A temperatura da superfície do aquecedor PTC é controlada pelo próprio PTC e pode ser controlada desconectando o circuito, mas não ajustando a tensão.

3) Embora os PTCs sejam inerentemente altamente confiáveis e tenham uma longa vida útil, montagem inadequada pode resultar em energia e temperatura instáveis.

4) Ao usar vários PTCs, Eles devem estar conectados em paralelo, não em série.

Contate-nos

Aguardando seu e-mail, responderemos dentro de 12 horas com informações valiosas que você precisava.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt