Productcategorieën

- thermische zekering 32

- opbouwzekeringen 12

- thermistor 36

- PCB-gemonteerde zekeringhouder 27

- Kabelboom 6

- Blade-zekeringhouders 17

- thermostaat 50

- Elektrische zekering 24

- Automotive temperatuursensor 7

- Thermische stroomonderbreker 22

- Zekeringkast-houder 36

- Temperatuursensor 75

- Thermische schakelaar 68

- Auto zekering 20

- Zekeringen vastschroeven 8

Producttags

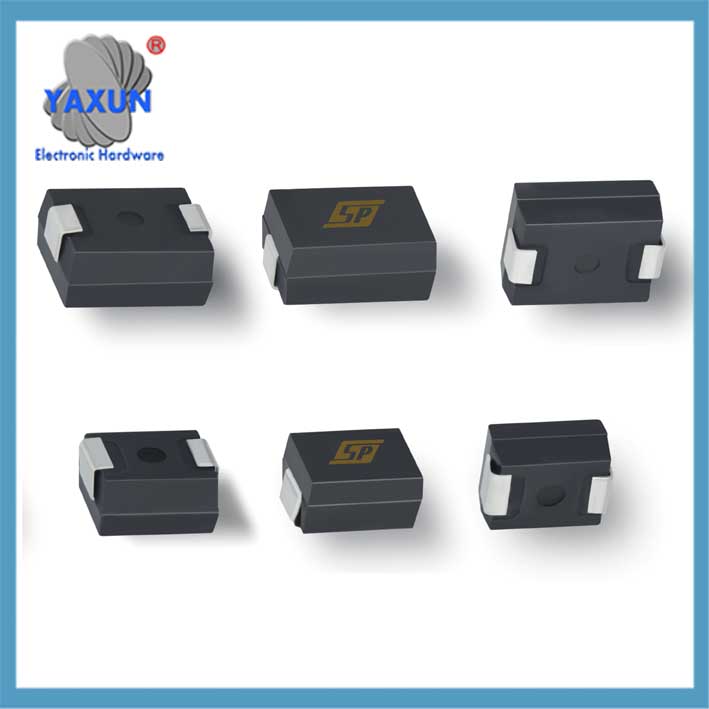

In kunststof ingekapselde chip-PTC-thermistor

In plastic ingekapselde chip-PTC-thermistors zijn thermistors met een positieve temperatuurcoëfficiënt (PTC's) verpakt in oppervlaktemontagetechnologie (SMD) verpakking. Ze worden veel gebruikt in circuitbeveiliging, temperatuurwaarneming, en geminiaturiseerde ontwerpen van elektronische apparaten.

In plastic ingekapselde chip-PTC-thermistors zijn thermistors met een positieve temperatuurcoëfficiënt (PTC's) verpakt in oppervlaktemontagetechnologie (SMD) verpakking. Ze worden veel gebruikt in circuitbeveiliging, temperatuurwaarneming, en geminiaturiseerde ontwerpen van elektronische apparaten. The following are their key features and selection considerations:

I. Core Features

Temperature Response Mechanism

Bij kamertemperatuur, the resistance is low (typically 1-20Ω). When the temperature exceeds the Curie point (BIJV., 105°C), the resistance increases stepwise (up to several thousand ohms), providing self-current limiting.

The polymer matrix (PPTC) expands when overcurrent occurs, severing the conductive path and automatically recovering after the fault is resolved.

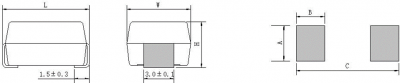

Packaging Advantages

Encapsulated with epoxy resin, they offer compact dimensions (BIJV., 4524 En 2822 packages), making them suitable for high-density PCB layouts.

They are resistant to high temperatures and humidity, meet UL94-V0 flame retardancy standards, and are suitable for lead-free reflow soldering processes. RoHS-compatibel

Suitable for lead-free wave soldering and reflow soldering of surface mount technology

Plastic encapsulated chip package, materials meet UL 94 V-0 flame retardancy requirements

Utilizes high-performance thermistor chip for compact size and high performance

Maintains stable performance over a long period of time

Breed bedrijfstemperatuurbereik: -40°C to 85°C

II. Selection Parameters

| Parameters | Typische waarde/bereik | Beschrijving |

|---|---|---|

| Zero-Power Resistor | 1-20Oh | Initial resistance affects circuit power consumption |

| Curie Temperature | 75-250℃ | Temperature threshold for triggering protection |

| Maximum Operating Voltage | ≤250V | Must match circuit voltage level |

| Action Time | Milliseconds | Fast response to overcurrent or overtemperature events |

III. Typische toepassingen

Electrical instruments;

Security equipment;

Communicatieapparatuur;

Huishoudelijke apparaten;

Automotive electronics;

Other power products requiring overcurrent, overspanning, and surge protection

Circuitbeveiliging: For overcurrent protection of USB ports and battery packs.

Temperature Compensation: Linear PTC models (such as the CMZ series) simplify temperature compensation design for precision circuits.

Automotive electronics: Meets wide operating temperature range of -40°C to 200°C.

Iv. Technical Comparison

| Type | Voordelen | Limitations |

|---|---|---|

| Ceramic PTC | High voltage resistance, high stability | Non-linear resistance-temperature curve |

| Polymer PPTC | Self-recovery, snel antwoord | Low withstand voltage (typically ≤60V) |

V. Mainstream Market Models

| Item

Model Specifications |

Zero Power Resistance @ 25°C | Curie Temperature | Operating Current @ 25°C | Non-Operating Current @ 60°C | Maximale stroom | Maximale spanning |

|

Rn(Ω) |

Tc(℃) |

Het(mA) |

Ih(mA) |

IMAX(A) |

Vmax(V) |

|

|

SPSMD4032H450R#450 |

45 |

83±7 |

150 |

25 |

* |

450 |

|

SPSMD3225H450R#300 |

45 |

83±7 |

100 |

18 |

* |

300 |

|

SPSMD3225M450R#300 |

45 |

105±7 |

150 |

42 |

0.3 |

300 |

|

SPSMD3225M600R#300 |

60 |

105±7 |

130 |

38 |

0.3 |

300 |

|

SPSMD3225S121R#300 |

120 |

115±7 |

100 |

32 |

0.3 |

300 |

|

SPSMD3225S151R#450 |

150 |

115±7 |

95 |

28 |

0.3 |

450 |

|

SPSMD3225S251R#450 |

250 |

115±7 |

80 |

25 |

0.3 |

450 |

|

SPSMD3225S301R#450 |

300 |

115±7 |

70 |

20 |

0.3 |

450 |

|

SPSMD3225S501R#450 |

500 |

115±7 |

55 |

15 |

0.3 |

450 |

|

SPSMD40325S600R#420 |

60 |

115±7 |

160 |

45 |

0.8 |

420 |

|

SPSMD4032S800R#450 |

80 |

115±7 |

140 |

40 |

0.8 |

450 |

|

SPSMD4032S101R#450 |

100 |

115±7 |

120 |

35 |

0.8 |

450 |

|

SPSMD4032S151R#450 |

150 |

115±7 |

100 |

30 |

0.8 |

450 |

|

SPSMD4032S301R#450 |

300 |

115±7 |

80 |

25 |

0.8 |

450 |

|

SPSMD4032S501R#450 |

500 |

115±7 |

65 |

18 |

0.8 |

450 |

|

SPSMD3225H102R#550 |

1000 |

83±7 |

25 |

5 |

0.1 |

550 |

|

SPSMD3225H152R#650 |

1500 |

83±7 |

25 |

4 |

0.1 |

650 |

|

SPSMD3225H202R#650 |

2000 |

83±7 |

25 |

3 |

0.1 |

650 |

*SPSMD4032H450R#450 和SPSMD3225H450R#300 分别可用于 485 通讯接口保护抗 380VAC 和 220VAC。

JK-EK Series: 4524/2822 pakket, CQC/UL certified, suitable for LEDs and industrial equipment.

CMZL Series: Linear PTC, with controllable resistance-temperature gradient (±2000ppm/°C), suitable for automotive and medical applications.

Plastic-encapsulated chip PTC thermistors balance protection performance and space efficiency through an integrated design, making them an ideal solution for compact electronic devices.

VI. Voorzorgsmaatregelen

General

To ensure the reliability of chip thermistors in actual use, extreme operating conditions should be considered during the design phase, and a certain margin should be allowed. Operating Environment

Omgevingstemperatuur: -40-125°C

Relative Humidity: ≤95%

Atmospheric Pressure: 86-106 kPa

Vibration Frequency: 10-50 Hz

Acceleration: 98 m/s²

Storage

The chip thermistor should be stored in its original packaging. Do not open the packaging for storage.

Original Packaging Storage Conditions: Storage Temperature -25°C to +45°C, Annual Average Relative Humidity ≤75%, Maximum Not Exceeding 95%.

For chip thermistors, avoid contamination of the thermistor terminal surfaces during storage, handling, and processing.

SMD thermistors should be stored in environments that could affect their performance.

Use the chip thermistor within one year of receipt. After this time, recheck the solderability of the electrodes.

Transportation

The thermistor should be protected from dropping and impact during transportation.

It is recommended to wear gloves when handling the thermistor.

For chip thermistors, avoid contamination of the thermistor solder terminals during transportation.

Soldering (where applicable)

Sn96.5Ag3.0Cu0.5 solder paste is recommended.

Insufficient preheating may cause cracks in the thermistor ceramic chip.

The recommended maximum soldering temperature is 255±5°C for 3-6 seconden. Excessive soldering temperatures and extended soldering times may damage the thermistor.

Rapid cooling by immersion in solvent is not recommended.

After soldering, it is recommended to completely remove the flux or use a no-clean flux.

Neem contact met ons op

Wachten op uw e-mail, wij zullen u binnen antwoorden 12 uur met waardevolle informatie die u nodig had.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt