Kategori produk

- sekering termal 32

- sekering dudukan permukaan 12

- termistor 36

- PCB Mount Fuse Holder 27

- Kabel harness 6

- Pemegang sekering pisau 17

- termostat 50

- Sekering listrik 24

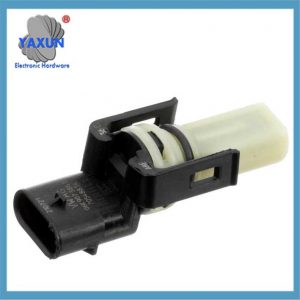

- Sensor suhu otomotif 7

- Pemutus sirkuit termal 22

- Pemegang kotak sekering 36

- Sensor suhu 75

- Sakelar termal 68

- Sekering mobil 20

- Bolt Down Fuses 8

Tag produk

Fungsi dan Klasifikasi Sensor Suhu Otomotif

Sensor suhu otomotif adalah komponen inti dari sistem manajemen termal kendaraan ( Sensor suhu cairan pendingin, Sensor suhu udara masuk, Sensor suhu oli transmisi, Sensor suhu eksternal/Interior), yang menyediakan data penting untuk unit kontrol mesin (ECU) untuk mengoptimalkan kinerja kendaraan dengan memantau perubahan suhu di berbagai area. Klasifikasi dan fungsinya yang utama adalah sebagai berikut:

Temperature sensors are widely used in automobiles, such as coolant temperature sensors (water temperature sensors), intake temperature sensors, transmission oil temperature sensors, dll.. The main function of these sensors is to monitor the temperature of different parts and feed back the data to the ECU to adjust the operating parameters of the engine and vehicle systems.

The next thing to consider is the type and working principle of the sensor. Commonly used ones are negative temperature coefficient thermistors (NTC), termokopel, platinum resistance detectors (Rtd), dll.. Diantaranya, NTC is the most widely used. Misalnya, the water temperature sensor uses the characteristic that the resistance of NTC decreases with increasing temperature. Silicon-based sensors such as KTY84 are used in higher precision occasions, such as oil temperature detection. The measurement range and accuracy of different sensors have their own characteristics. Misalnya, thermocouples are suitable for high temperature environments, but the accuracy is low; platinum resistance detectors have high accuracy but high cost.

The installation location is also critical. Misalnya, the water temperature sensor is usually near the water jacket of the engine block or cylinder head, while the intake temperature sensor is in the intake pipe or air flow meter. The location of the external temperature sensor varies, some are in the front bumper, some are near the water tank, and the difference between different models is large. The choice of these locations directly affects the accuracy of the measurement and the durability of the sensor.

In terms of function, the temperature sensor has a great impact on vehicle performance. Abnormal water temperature sensors can cause problems such as difficult cold starts, kecepatan idle tidak stabil, and increased fuel consumption. Failure of the intake temperature sensor may cause an imbalance in the mixture ratio and affect power output. These failure cases illustrate the importance of sensors, especially the impact of data inaccuracy on ECU decision-making.

The fault handling section needs to summarize common problems and solutions. Misalnya, signal drift, line aging, physical damage, dll.. During diagnosis, the actual temperature can be compared by measuring resistance, voltage or data flow. Here we should emphasize the importance of regular maintenance and correct installation to avoid major failures caused by minor problems.

Akhirnya, the development of new technologies is also improving the performance of sensors. Misalnya, Continental’s eRTS sensor can directly measure the temperature of the motor rotor with an accuracy of ±3°C, reducing the use of rare earth materials. This innovation demonstrates the progress of temperature sensors in the field of electric vehicles.

🔧 Saya. Core types and technical principles

Sensor suhu cairan pendingin

Location: Blok silinder mesin/jaket air kepala silinder (mainstream position for 65% of models), near the thermostat or coolant shunt pipe.

Principle: Using negative temperature coefficient thermistor (NTC), the resistance drops to 0.3kΩ at 80℃ (2.5kΩ at 20℃).

Function: Correct low temperature injection amount (+30% kompensasi start dingin), adjust ignition advance angle (-20℃ advance 8–12°), control idle speed (low temperature rises to 1200–1500rpm).

Sensor suhu udara masuk

Location: Intake pipe or inside air flow meter 5.

Impact: Abnormal signal leads to mixture imbalance, causing cold start difficulty or weak acceleration.

Transmission oil temperature sensor

Location: Inside the oil pan of the automatic transmission valve plate 5.

Function: Provide temperature basis for shift logic, oil pressure control and locking clutch.

Exterior/interior temperature sensor

Exterior: Behind the front bumper or the front wall of the cab, controlling the temperature zone of the automatic air conditioner.

Interior: The ventilation duct under the instrument panel monitors the ambient temperature of the cabin.

⚙️ II. Technological evolution and innovation

| Jenis sensor | Lokasi instalasi | Fungsi | Persyaratan akurasi |

| Sensor suhu cairan pendingin | Cylinder head water jacket/thermostat periphery | Correct fuel injection amount (suhu rendah +30% kompensasi), adjust ignition angle (8-12° in advance at -20°C) | ±3°C (2025 new model) |

| Sensor suhu masuk | Intake pipe or air flow meter | Correct air-fuel ratio, failure will cause hot start difficulty and excessive emissions | ±5℃ |

| Sensor suhu oli transmisi | Inside valve plate oil pan | Control shift logic and oil pressure to prevent lubrication failure caused by high temperature | ±2℃ |

| Sensor suhu gas buang | Behind three-way catalytic converter | Monitor catalyst overheating (300-400°C working condition) and trigger protection mechanism | ±15℃ |

| Motor rotor temperature sensor | Inside permanent magnet synchronous motor rotor | Directly monitor magnet temperature to prevent high temperature demagnetization at 150°C and reduce rare earth usage | ±3°C (eRTS technology) |

| Battery temperature sensor | Battery pack thermal management area | Ensure the lithium battery operating temperature range (-20℃~60℃) to prevent thermal runaway | ±1℃ |

Breakthrough in precision measurement: The new eRTS sensor directly measures the motor rotor temperature through piezoelectric ultrasonic technology, with an accuracy increased from ±15℃ to ±3℃, reducing dependence on rare earth materials.

Material upgrade: The silicon-based KTY84 sensor can work at -40℃~300℃, and its linear resistance-temperature characteristics are suitable for high-temperature scenarios such as diesel injection systems.

⚠️ III. Typical faults and diagnosis

IV. Differences in installation position and impacts

Same function, different position: The external temperature sensor is located in the drain groove or front bumper of the Sagitar model, while some models are integrated under the rearview mirror.

Accuracy correlation: When the coolant sensor is in direct contact with the liquid, the error is ≤±15℃, and the indirect calculation (such as the motor stator inferring the rotor) has an error of up to 15℃.

💎 Ringkasan

The temperature sensor is like the “nerve endings” of the car, and its accuracy directly affects the power output efficiency and energy consumption. Dengan berkembangnya kendaraan listrik, high-precision direct measurement technology (such as eRTS) is gradually replacing the indirect inference mode, promoting the refined revolution of the thermal management system. Regular detection of resistance characteristics and signal stability is the key to preventing systemic failures.

Hubungi kami

Menunggu email Anda, kami akan membalas Anda di dalam 12 jam dengan informasi berharga yang Anda butuhkan.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt